If you're looking for the best concrete expansion joint sealant, there are a few factors you should consider before making your purchase. First and foremost, it's important to choose a sealant that is specifically designed for use on concrete surfaces. This will ensure that the product is able to withstand the wear and tear that can come with outdoor exposure. Additionally, you'll want to look for a sealant that is easy to apply and long-lasting, so you don't have to spend time and money reapplying it every year.

When choosing a concrete expansion joint sealant, it's also important to consider the climate in your area. If you live in an area that experiences extreme temperatures or frequent freeze-thaw cycles, you'll need a sealant that is designed to withstand these conditions. Additionally, you'll want to choose a sealant that is resistant to UV rays, as exposure to sunlight can cause some products to break down over time.

Are you tired of dealing with unsightly cracks in your concrete driveway or patio? Do you want to protect your investment and ensure that it lasts for years to come? If so, a high-quality concrete expansion joint sealant may be the solution you've been looking for. Keep reading to discover some of the best options on the market, and find the product that's right for you!

10 Best Concrete Expansion Joint Sealant

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

This product is ideal for repairing damaged mortar, joints, and gaps as well as sealing mortar cracks.

|

|

||

|

2

|

This product is ideal for repairing cracks in concrete foundations with an easy-to-remove surface sealer for hassle-free clean-up.

|

|

||

|

3

|

The product is ideal for homeowners who want to DIY repair basement cracks and stop water leakage through concrete foundations.

|

|

||

|

4

|

This product is ideal for repairing cracks in concrete surfaces.

|

|

||

|

5

|

The product is ideal for filling and sealing cracks in concrete surfaces such as driveways, sidewalks, and patios.

|

|

||

|

6

|

It is ideal for filling and sealing cracks in concrete surfaces.

|

|

||

|

7

|

Sealing horizontal expansion joints in concrete quickly and efficiently.

|

|

||

|

8

|

Product is ideal for sealing and filling concrete and mortar to make them watertight.

|

|

||

|

9

|

Ideal for sealing joints up to 1/2" in a variety of applications, with an all-purpose polyurethane elastomeric sealant.

|

|

||

|

10

|

It's ideal for sealing cracks and joints in concrete and can be painted over after application.

|

|

1. Sika Limestone Mortar Sealant – Repair & Seal.

This sealant is perfect for any joint where the depth of the sealant will not exceed half an inch. It has numerous benefits, including hiding imperfections caused by tooling and providing high elasticity. The sealant cures to a tough, durable, and flexible consistency, with exceptional cut and tear resistance. It can be painted with water-based, oil-based, or rubber-based paints, making it versatile for any project.

This sealant is ideal for weatherproofing joints between brickwork, blockwork, masonry, concrete, or metal frames. It is perfect for use in walls, balconies, around window or door frames, and expansion joints.

The sealant boasts excellent resistance to aging and weathering, ensuring long-lasting performance. It can also be used at temperatures as low as 40 °F (4 °C).

Each cartridge of the sealant contains 10.1 fl. oz. (299 ml) and can create approximately 12 meters of joint. This makes it a cost-effective solution for any joint sealing needs.

2. Radonseal Concrete Crack Repair Kit – Easy Peel & Seal

The crack repair kit offers a convenient solution for repairing hairline cracks without drilling or grinding. The low-pressure injection method eliminates the need for excavation, saving users serious money. With the low-viscosity, 2-component injection urethane, the kit is suitable for repairing hairline cracks. Users can use a standard caulking gun to inject the solution, and no special tools are required.

The crack repair kit provides a permanent solution to prevent water seepage. It is impervious to water vapor, soil gases, and even radon, ensuring that the crack is repaired permanently. Additionally, the kit features an easy-peel epoxy surface sealer and injection ports that easily peel off for a clean finish.

With this crack repair kit, users can save money and time while achieving a permanent solution to hairline cracks. The kit's ease of use and lack of special tools required makes it an excellent choice for both DIY enthusiasts and professionals. The low-pressure injection method and low-viscosity urethane make it easy to repair cracks from the inside, eliminating the need for excavation. Users can achieve a clean finish with the easy-peel epoxy surface sealer and injection ports. This crack repair kit is an excellent investment for anyone looking for a permanent solution to hairline cracks.

3. Quick-Fix Crack Repair Kit – Waterproof Concrete Solution

Looking for a solution to stop water leaks through concrete foundation cracks? Look no further than this fast curing surface sealer and injection polyurethane foam, designed to provide the same high-quality results as the materials used by professional customers.

The product includes a how-to video to guide you through the application process, making it easy to achieve professional-grade results in no time. The polyurethane foam is designed to tightly bond to the concrete, providing a better injection process and ensuring that water leaks are stopped in their tracks.

With its fast curing time, this product is an ideal choice for those looking to quickly and effectively repair concrete foundation cracks. It's easy to use and provides long-lasting results that you can count on.

So why wait? Choose this fast curing surface sealer and injection polyurethane foam today and say goodbye to water leaks through your concrete foundation cracks for good!

4. Sashco – 16210-12 Slab Concrete Crack Repair Sealant, 10.5 Ounce Cartridge, Gray (Pack Of 12)

The Slab concrete sealant is designed to provide a weatherproof seal that moves with your concrete, making it an ideal solution for addressing shifting soils, temperature fluctuations, moisture, and traffic. With its extreme elasticity, Slab is able to banish dandelions, anthills, and other unsightly crack dwellers for good.

One of the biggest advantages of using Slab is that it minimizes the need for repeated concrete repairs. Unlike brittle, cracked concrete repairs, Slab is formulated with tenacious adhesion to concrete, allowing it to create a perfect balance of sticking and stretching. This means that repairs last for years, rather than just months.

Slab is also designed to blend in seamlessly with aged concrete, thanks to its textured and colored finish. This ensures that the sealant won't stick out or detract from the appearance of your concrete surfaces.

In addition to being highly effective, Slab is also incredibly easy to use. It can easily be smoothed and cleaned up with water, without requiring any special chemicals or tools. And, unlike some other sealants, Slab is freeze-thaw stable through 10 cycles, making it safe to leave in your unheated garage overnight.

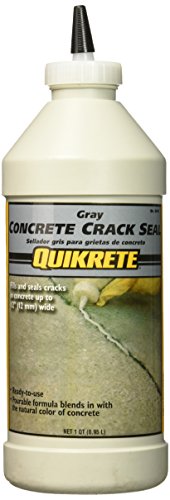

5. Quikrete Concrete Crack Seal Natural 1 Qt

This product has been designed to make your life easier. With its user-friendly interface, it is easy to operate and can be used by anyone without prior technical knowledge. The product has been tested thoroughly to ensure its durability, and you can be confident that it will last for a long time.

This product has been manufactured in China, a country known for its high-quality manufacturing processes. The product has undergone rigorous testing and quality control measures to ensure that it meets the highest standards.

The product boasts of several parameters that make it stand out. It is lightweight and compact, making it easy to carry around. It is designed to be energy-efficient, which means that it consumes less power and helps you save on your electricity bills. The device is equipped with the latest technology, ensuring that you get the best performance and reliability.

The product is made of high-quality materials that ensure its durability and longevity. The device is designed to withstand wear and tear, making it the perfect choice for long-term use. The product is also easy to clean and maintain, ensuring that it remains in top condition for years to come.

6. Dap 18096 10.1 Oz. Concrete Waterproof Filler And Sealant, Gray (12 Pack)

This 10.3 oz. cartridge of siliconized latex is the perfect solution for sealing cracks in concrete and masonry. With its specialized formula, it can easily fill in gaps and crevices in steps, driveways, sidewalks, and mortar joints, providing a durable and long-lasting seal.

The cartridge is designed to be easy to use and can be applied with standard caulking guns, making it perfect for DIY enthusiasts and professionals alike. Its unique formulation ensures that it adheres strongly to both vertical and horizontal surfaces, providing a secure and reliable seal against water, dust, and other contaminants.

With a weight of 10.3 oz., this cartridge provides enough material to cover a significant area, making it an excellent value for money. Its siliconized latex composition ensures that it remains flexible even in extreme temperatures, preventing it from cracking or breaking under stress.

7. Fast-Seal Gray Concrete Joint Sealer

Introducing a premium quality sealant for your concrete needs – the concrete self-leveling caulk. With its exceptional performance, this product is designed to meet your sealing requirements without the need for tooling. Its self-leveling feature ensures a smooth and even finish, making it the perfect solution for leveling uneven surfaces.

This sealant is water immersible and waterproof after curing, ensuring a long-lasting and reliable seal. Its permanent elasticity allows for flexibility, making it resistant to cracking and breaking. Additionally, it can be painted with water-based, oil-based or rubber-based paints, providing versatility in its application.

Boasting excellent adhesion on concrete and cementitious slabs, this self-leveling caulk can bridge gaps up to 1.5 inches wide. Its high durability and resistance to ageing and weathering makes it a reliable solution for your sealing needs.

This product is perfect for a variety of applications, including driveways, garages, sidewalks, balconies, pavements, terraces, warehouses, factories, civil structures and plazas. Its exceptional performance, reliability, and versatility make it the ideal choice for all of your concrete sealing requirements.

8. Dap Water Sealant Trio: Gray Mortar Filler Pack

The 10.3 oz. Cartridge of Siliconized Latex is an exceptional product that seals cracks in concrete and masonry. It is a versatile product that is commonly used in steps, driveways, sidewalks, and mortar joints. Each pack contains three cartridges of the product, ensuring that you have enough to complete your project without the need for frequent purchases.

One of the standout features of this product is its siliconized latex composition. This unique blend of materials allows for a durable and long-lasting seal that is resistant to moisture and weathering. It is also flexible, which means it can withstand the expansion and contraction of materials that occurs naturally over time.

The 10.3 oz. cartridge size is perfect for small to medium-sized projects. Its compact size makes it easy to handle and apply, without the need for specialized equipment. It also has a precision tip that allows for accurate application, ensuring that the product is applied only where it is needed.

This product's versatility is another significant advantage. It can be used in a variety of applications, including steps, driveways, sidewalks, and mortar joints. This makes it an excellent choice for homeowners and professionals alike, as it can be used in a range of projects from small-scale repairs to larger-scale renovations.

9. Sikaflex Limestone Sealant: Versatile Joint Solution

The Sikaflex Construction Sealant is a versatile polyurethane solution designed to effectively seal joints and gaps in various construction projects. It boasts impressive performance, with the ability to accommodate up to ±35% joint movement. Furthermore, it can be painted with water-based, oil-based, and rubber-based paints, providing flexibility in its usage.

When it comes to durability, the Sikaflex Construction Sealant does not fall short. Its high elasticity allows it to cure into a tough, flexible consistency with exceptional cut and tear resistance. It also boasts excellent resistance to aging and weathering, ensuring long-lasting results for any project.

The Sikaflex Construction Sealant supports bonding to most construction materials without the need for a primer. This makes it an excellent choice for weatherproofing joints between brickwork, block-work, masonry, wood, concrete, or metal frames.

The Sikaflex Construction Sealant can be used for various applications, including sealing joints in walls, floors, balconies, and around window or door frames. It is also suitable for sealing expansion joints, making it a versatile solution for any construction project.

10. Sika Limestone Concrete Crack Sealant.

This elastic sealant is designed to effectively seal all types of joints and cracks where the maximum depth of the sealant will not exceed 1/2 in. (12.7mm). It is a high-performance sealant that is suitable for both vertical and horizontal joints and can be used at temperatures as low as 40°F (4°C).

This sealant boasts a joint movement capability of ±35%, making it ideal for weatherproofing joints, cracks, and gaps in concrete, brickwork, blockwork, masonry, stucco, and metal frames. It is suitable for use on joints in walls, floors, balconies, around window or door frames, expansion joints, and roofing.

Durability is one of this sealant's top features, as it has excellent resistance to aging and weathering. It is also highly durable, flexible, and boasts exceptional cut and tear resistance.

This sealant can be applied on green/new concrete 24 hours after it has hardened and on concrete that has been wet for 1 hour after the water source has stopped. It can also be painted with water-based, oil-based, or rubber-based paints, making it an excellent choice for a wide range of sealing applications.

Best Concrete Expansion Joint Sealant FAQs

Can I apply concrete expansion joint sealant in extreme weather conditions?

It is not recommended to apply concrete expansion joint sealant in extreme weather conditions as it can affect the performance and durability of the sealant. High temperatures can cause the sealant to dry too quickly, leading to cracking and shrinking. On the other hand, cold temperatures can hinder the curing process and affect the adhesion of the sealant. It is best to apply the sealant when the temperature is between 50°F and 90°F (10°C and 32°C) and the humidity is low. Additionally, it is important to ensure that the surface is dry and free from debris before applying the sealant. If you need to apply sealant in extreme weather conditions, you may need to use specialized sealants that are designed for such conditions. It is always advisable to consult a professional or the manufacturer's guidelines for specific instructions before applying any sealant.

How do I prepare the surface before applying concrete expansion joint sealant?

Before applying concrete expansion joint sealant, it is important to prepare the surface properly to ensure maximum adhesion and longevity of the sealant. Here are the steps to prepare the surface:

1. Clean the surface: Remove all dirt, debris, and loose particles from the surface using a wire brush, power washer, or compressed air. Make sure the surface is completely dry before moving on to the next step.

2. Fill any cracks or gaps: If there are any cracks or gaps in the concrete, fill them with a concrete patching compound and allow it to dry completely.

3. Smooth the surface: Use a grinder or sander to smooth out any rough spots or high spots on the surface. This will ensure that the sealant adheres evenly.

4. Apply primer: Apply a concrete primer to the surface to improve adhesion of the sealant. Make sure to follow the manufacturer's instructions for application and drying time.

5. Apply sealant: Once the primer is dry, apply the concrete expansion joint sealant according to the manufacturer's instructions. Use a putty knife or caulking gun to apply the sealant evenly, and make sure to fill the joint completely.

By following these steps, you can ensure a properly prepared surface for applying concrete expansion joint sealant, which will help to prolong the life of the sealant and prevent future damage to the concrete.

How long does a concrete expansion joint sealant last?

The lifespan of a concrete expansion joint sealant largely depends on various factors such as the type of sealant used, the quality of the installation, and the amount of traffic the concrete surface experiences. Generally, most sealants are designed to last between five to ten years, but some high-quality sealants can last up to 25 years.

To ensure the maximum lifespan of a concrete expansion joint sealant, it is essential to choose a high-quality sealant that is appropriate for the specific application. The sealant should also be installed correctly, with the right amount of depth and width, and the appropriate amount of adhesive applied.

Furthermore, regular maintenance and inspection of the sealant are also crucial to ensure its longevity. This includes regular cleaning of the sealant to prevent debris buildup and monitoring for any signs of cracks or gaps.

In conclusion, the lifespan of a concrete expansion joint sealant varies depending on several factors, and proper installation, selection, and maintenance are essential to ensure the sealant lasts as long as possible.

How long should I wait before allowing traffic on newly sealed concrete expansion joints?

The time required before allowing traffic on newly sealed concrete expansion joints depends on several factors such as the type of sealant used, weather conditions, and the intensity of traffic. Generally, it is recommended to wait for at least 24 hours before allowing foot traffic and 72 hours before allowing vehicular traffic on newly sealed concrete expansion joints.

However, it is essential to check the manufacturer's instructions for the specific sealant you used, as some sealants may require a longer curing period. Additionally, if the weather conditions are humid or rainy, it may prolong the curing time.

It is crucial to follow the recommended curing time before allowing traffic on newly sealed concrete expansion joints to ensure that the sealant has fully cured and is durable enough to withstand the traffic load. Rushing the curing process may lead to premature sealant failure, which can lead to costly repairs.

How much sealant is needed per linear foot of expansion joint?

The amount of sealant required per linear foot of expansion joint depends on the width and depth of the joint. Generally, a standard rule is to use 1/2 to 3/4 of a gallon of sealant per 100 linear feet of joint for a 1/2 inch deep and 1/2 inch wide joint. However, for larger joints, the amount of sealant required will be higher. It is important to read the manufacturer's instructions carefully to determine the exact amount of sealant required for the specific expansion joint being used. Factors such as temperature, humidity, and joint movement will also affect the amount of sealant required. It is always recommended to order slightly more sealant than required to avoid running out during the installation process. Proper application of the sealant is crucial to ensure that the joint is properly sealed and to prevent any future issues.

What are the benefits of using the best concrete expansion joint sealant?

The use of the best concrete expansion joint sealant brings several benefits. Firstly, it provides protection to the concrete surface by preventing moisture and debris from entering the joints, which ultimately extends the life of the concrete. Secondly, it helps to maintain the structural integrity of the concrete by minimizing the risk of cracks and damage caused by the expansion and contraction of the concrete due to temperature changes. Thirdly, it enhances the aesthetics of the concrete by providing a smooth and uniform surface, which is especially important for areas with heavy foot traffic. Additionally, the sealant improves the safety of the surface by reducing the risk of tripping and falling due to uneven joints. Finally, it is cost-effective as it helps to reduce the need for frequent repairs and maintenance, saving time and money in the long run. Overall, the use of the best concrete expansion joint sealant provides a durable and long-lasting solution that ensures the longevity and safety of the concrete surface.

What are the best types of concrete expansion joint sealants available in the market?

There are several types of concrete expansion joint sealants available in the market, each with its own unique advantages and disadvantages. The most common types of sealants include silicone, polyurethane, and polysulfide.

Silicone sealants are best suited for joints that will not be exposed to extreme temperatures or heavy traffic. They are easy to apply, have good adhesion, and are resistant to UV rays and weathering.

Polyurethane sealants are ideal for joints that will be exposed to heavy traffic and extreme temperatures. They have excellent adhesion, are flexible, and can withstand movement without cracking. They are also resistant to chemicals and UV rays.

Polysulfide sealants are best suited for joints that will be exposed to water and chemicals. They have excellent adhesion, are highly elastic, and can withstand a wide range of temperatures. They are also resistant to UV rays and weathering.

When choosing a concrete expansion joint sealant, it is important to consider the specific requirements of the project and choose a sealant that is compatible with the concrete and the environment in which it will be used. It is also important to follow the manufacturer's instructions for application and maintenance to ensure maximum performance and longevity.

What are the common problems associated with concrete expansion joint sealants?

Concrete expansion joint sealants are essential for preventing water, debris, and other foreign materials from entering the joints of concrete structures. However, like any other construction material, they are prone to certain problems. One of the most common issues is cracking. This can happen due to exposure to extreme temperatures, excessive joint movement, or poor installation. Cracks can compromise the sealant's ability to prevent water infiltration, which can lead to corrosion and other structural damages.

Another issue is delamination, where the sealant separates from the concrete surface. This can occur due to poor surface preparation or inadequate adhesion of the sealant. Delamination can also compromise the effectiveness of the sealant, allowing water and debris to enter the joint.

Lastly, discoloration is another common problem with concrete expansion joint sealants. This can happen due to exposure to UV radiation, weathering, or chemical exposure. Discoloration can impact the aesthetic appeal of the structure, but it does not affect the sealant's functionality.

Overall, proper installation, regular maintenance, and timely repairs can help mitigate these problems and ensure the longevity of the concrete expansion joint sealants.

What are the key factors to consider when selecting the best concrete expansion joint sealant?

When selecting the best concrete expansion joint sealant, there are several key factors to consider. The first factor is the type of joint that needs to be sealed. Different types of joints require different types of sealants, so it’s important to choose a sealant that is specifically designed for the type of joint you are working with.

Another important factor is the expected movement of the joint. If the joint is expected to move a lot, then you need to choose a sealant that is flexible and can accommodate the movement without cracking or breaking.

The environment in which the joint is located is also an important consideration. If the joint is exposed to harsh weather conditions or chemicals, then you need to choose a sealant that is resistant to those conditions.

The application method is also a factor to consider. Some sealants require special equipment or tools for application, while others can be applied by hand.

Finally, the cost of the sealant should also be considered. While it’s important to choose a high-quality sealant, it’s also important to choose one that fits within your budget. By considering these key factors, you can select the best concrete expansion joint sealant for your specific needs.

What is the best method for applying concrete expansion joint sealant?

The best method for applying concrete expansion joint sealant will depend on the specific product being used. However, there are some general guidelines that can be followed to ensure a successful application.

Firstly, it is important to properly clean and prepare the joint before applying the sealant. This may involve removing any debris or old sealant, and ensuring the joint is dry and free from dust or other contaminants.

Next, the sealant should be applied using a caulking gun, being careful to fill the joint completely without over-applying. It is important to follow the manufacturer's instructions regarding the application rate and curing time.

Some sealants may require a backing material to be placed in the joint before applying the sealant, while others may not. Again, it is important to follow the manufacturer's instructions regarding the specific product being used.

After applying the sealant, it should be left to cure fully before allowing any traffic or movement over the joint. Regular maintenance and re-application may be necessary over time to ensure the joint remains properly sealed.