If you’re looking for the best epoxy for gas tank repair, then you’ve come to the right place. Choosing the right epoxy is important as not all epoxies are created equal. You want an epoxy that is strong, durable, and can withstand the harsh conditions of a gas tank.

Before buying any epoxy, readers need to consider a few factors. Firstly, it's important to know if the epoxy can work with the material of their gas tank. Next, readers need to check if the epoxy is easy to apply. Finally, they should consider the curing time of the epoxy, so that they can know how much time they have before the epoxy sets and becomes hard.

Wouldn’t it be great if you could repair a gas tank and avoid costly auto repairs? That’s where the best epoxy for gas tank repair comes in. But with so many options available, how do you choose the right one? How can you be sure that the epoxy you use is durable and long-lasting? Which epoxy brands should you trust? Keep reading to discover the answers to these questions and more.

10 Best Epoxy For Gas Tank Repair

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

Ideal for repairing and bonding aluminum surfaces, including tanks, pipes, gutters, and other metal parts.

|

|

||

|

2

|

This product is ideal for bonding and repairing various materials quickly, with a cure time of five minutes.

|

|

||

|

3

|

Ideal for building and repairing fiberglass and wood boats, and other marine-grade applications.

|

|

||

|

4

|

The product is ideal for repairing fuel tanks, leaks, and cracks.

|

|

||

|

5

|

This epoxy adhesive paste is ideal for marine applications due to its two-part marine grade formula.

|

|

||

|

6

|

The product is ideal for repairing and bonding metal surfaces, filling gaps and holes, and fixing broken parts.

|

|

||

|

7

|

The product is ideal for making strong and durable repairs to metal surfaces, such as automotive parts and plumbing fixtures.

|

|

||

|

8

|

Ideal for coating, bonding, potting, reinforcing fiberglass and repairing, resistant to E85 gasoline and diesel fuel.

|

|

||

|

9

|

This product is ideal for marine repairs and bonding materials that will be exposed to water and moisture.

|

|

||

|

10

|

Ideal for repairing and filling cracks, holes, leaks, and other damages in aluminum surfaces or parts.

|

|

1. Hy-Poxy H-450 Alumbond 6.5 Oz Aluminum Putty Repair Kit

The Epoxy Metal Weld for Aluminum is a reliable and effective solution for repairing a wide range of materials such as HVAC systems, radiators, engine blocks, boat hulls, equipment, and appliances. This product is specially designed to provide a strong and long-lasting bond, ensuring that your repairs are secure and durable.

This versatile epoxy metal weld can be drilled, tapped, sanded, threaded, and painted, making it easy to use for a variety of applications. Its non-rusting and non-magnetic properties make it an ideal choice for repairing aluminum surfaces. Additionally, the product has an attractive aluminum gray color that stays intact even after sanding or polishing.

This product is proudly made in the USA, ensuring that you receive a high-quality and reliable product. With its exceptional performance, you can be confident that your repairs will last for a long time. Whether you are a professional mechanic or a DIY enthusiast, this epoxy metal weld for aluminum is a must-have in your toolbox.

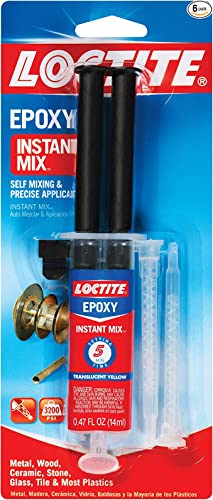

2. Loctite Epoxy Five Minute Instant Mix 0.47-Fluid Ounce Syringe, Hc1060027 (1365868)

The Loctite Epoxy Instant Mix 5 Minute is an ideal solution for those who need a reliable adhesive or filler. This product is designed to bond a variety of materials such as wood, metal, tile, ceramic, glass, plastic, and more. The self-mixing dispenser and precision applicator make it easy to use, allowing for precise application.

This high-strength formula is waterproof, sandable and paintable, making it the perfect solution for both indoor and outdoor applications. It can be used as an adhesive for a wide range of materials or as a versatile filler for gap bonding, surface repairs, and laminating. It does not shrink and is resistant to water and most common solvents, ensuring durability and longevity.

The Loctite Epoxy Instant Mix 5 Minute comes with a static mix nozzle that delivers a uniform mixture of resin and hardener every time. This ensures consistent and reliable results every time you use it. Additionally, it can be tinted with earth pigments, cement or sand for color matching and can be sanded and drilled, providing flexibility in its usage.

This product is recommended for bonding metal, glass, ceramic, wood, many rigid plastics, china, tile, fiberglass, concrete and stone. Its versatility and strength make it a go-to adhesive for both DIYers and professionals alike.

3. Marine-Grade Epoxy Resin Kit For Boat Repair

The Premium Epoxy Kits are the perfect solution for anyone looking to undertake boat building, composite construction, or epoxy repair projects. This kit comprises of 5:1 marine epoxy resin and hardener, providing enough material to complete an array of projects. The kit is suitable for use on various surfaces such as wood, fiberglass, reinforcement fabrics, etched aluminum, bare steel, and lead. However, it is not recommended for clear-coating applications.

The ideal viscosity of the epoxy kit allows for wetting out fiberglass cloth and other reinforcement fabrics with ease. The self-leveling properties of the kit make it ideal for coating and laminating. Users can also mix the epoxy with fillers to create a high-strength fairing compound, filleting material, or adhesive, making it an incredibly versatile product.

The kit comes with the option to choose between fast or slow hardener, with the pot life ranging from 12 minutes at 75°F for the fast hardener to 20 minutes at 75°F for the slow hardener. This allows users to have better control over their project and ensure they have enough time to work with the epoxy before it starts to cure.

The Premium Epoxy Kits come in three sizes: quart, gallon, and 4.5 gallons, and users can choose between the Totalboat 5:1 fast or slow hardener. The kit includes resin, hardener, calibrated pumps, mixing sticks, and mixing cups, making it a complete package for any epoxy project. Additionally, the kit is compatible with other 5:1 epoxy resin systems, making it an excellent option for anyone looking to expand their epoxy kit collection.

4. Permatex 84334-12pk Fuel Tank Repair Epoxy Stick – 1 Oz., (Pack Of 12)

The product being reviewed is a highly advanced ethanol-resistant formula designed to provide superior performance in various applications. This product boasts an exceptional level of flexibility and tackiness, making it ideal for use in a variety of industrial and commercial settings.

One of the key features of this product is its non-shrinking formula, which ensures that it maintains its shape and size over time. Unlike other sticks that can crumble or become brittle, this product is designed to withstand even the most demanding conditions.

This innovative formula is also highly resistant to ethanol, making it ideal for use in environments where this substance is present. Whether you are working in a laboratory, factory, or other industrial setting, this product is sure to meet your needs.

5. Pc-Products Pc-11 Epoxy Adhesive Paste, Two-Part Marine Grade, 2oz In Two Jars, Off White 20111

This marine epoxy adhesive paste is a two-part bonding agent that is highly effective in dry, wet, and underwater environments. It is ideal for bonding a wide range of materials including fiberglass, concrete, metals, glass, ceramic, and rubber. The paste can be used for both indoor and outdoor applications, with a temperature range of 35 to 115 degrees F and a service temperature range -20 to +200 degrees F.

One of the unique features of this marine epoxy adhesive paste is its high-tack formula, which makes it ideal for use in vertical and overhead applications. It resists mild acids, caustics, detergents, gasoline, fuel oil, and fresh and saltwater, making it highly versatile for a wide range of applications.

The PC-11 formulation provides an extended working time, allowing the user to reposition work or make changes during large and critical jobs. The high "wet grab" or tack of PC-11 Paste Epoxy also makes overhead and sidewall work easy, without drip or sag.

In addition, PC-11 demonstrates excellent chemical resistance to mild acids, caustics, detergents, gasoline, fuel oil, salt and fresh water. It is important to note that PC-11 will not bond to wax paper, Teflon, Polyethylene, and some other plastics. It is recommended to test a small area when in doubt.

6. J-B Weld 8267 Steelstik Steel Reinforced Epoxy Putty Stick – 2 Oz.

Introducing J-B Weld Steelstik, the two-part epoxy putty stick that is steel reinforced and non-rusting, making it the perfect solution for quickly repairing or rebuilding anything made of metal. This product is certified by the NSF and is safe for contact with potable water.

The cure and set time for Steelstik is impressive, taking only 5 minutes to set after kneading the two-part formula together by hand, and curing completely in just 1 hour. The set and cure color of Steelstik is a sleek dark grey.

J-B Weld Steelstik boasts a range of impressive product features and strength. With lap shear strength of 900 psi, it can withstand continuous temperatures up to 350F (176C) and intermittent temperatures of 450F (232C). Moreover, it is chemical resistant against petroleum, hydraulic fluids, and other chemicals when fully cured. Steelstik can be molded, shaped, sanded, drilled, and tapped, making it a versatile and reliable solution for all your metal repair needs.

Steelstik works great on a variety of surfaces including iron and stainless steel, copper and brass, aluminum and bronze, fiberglass, and plastic & PVC. Its steel reinforcement ensures its durability, and its non-rusting properties make it a great long-term solution.

7. Versachem 44029 Magnum Steel Stick Epoxy – 2 Oz.

The Fast-curing, two-part epoxy putty stick is the ultimate solution for repairing leaks, holes, and cracks. This versatile product molds to any surface, ensuring a permanent fix that you can rely on.

With a handling time of just 3-4 minutes and a set time of 15 minutes, this epoxy putty stick is incredibly easy to use. Once fully cured, which takes 24 hours, it can be drilled, filed, sanded, and painted to match the surrounding surface.

This epoxy putty stick is ideal for repairing pipes, tanks, radiators, couplings, and much more. It's a must-have tool for any DIY enthusiast, plumber, or mechanic.

The parameters of this product make it a reliable and efficient solution for any repair job. The epoxy putty stick sets quickly and is durable enough to withstand high pressure and extreme temperatures. It's perfect for both indoor and outdoor use.

8. Max Gre Resin: Gas & Diesel Proof!

The Gasoline Resistant Epoxy Repair is a top-quality solution for repairing metal tanks and composite fuel cells. Designed to withstand the effects of E85 Gasoline and Bio-Diesel blends, this product is perfect for those who demand durability and long-lasting performance.

This epoxy repair boasts outstanding adhesion to metals and FRP tanks, ensuring that it remains firmly in place even under extreme conditions. It is also highly corrosion-resistant, which means that it can effectively prevent oxidation and other forms of damage that can occur over time.

Thanks to its impregnating resin, this epoxy repair can be used for carbon fiber and fiberglass patching and reinforcement. This feature makes it an ideal choice for those who need to reinforce or repair these types of materials.

Whether you need to repair a metal tank or a composite fuel cell, this gasoline-resistant epoxy repair is a reliable and effective solution. With its exceptional adhesion, corrosion resistance, and impregnating resin, you can trust that your repairs will be long-lasting and effective.

So if you're looking for a high-quality epoxy repair that can stand up to the toughest conditions, look no further than this gasoline-resistant epoxy repair. It's the perfect solution for all your metal tank and composite fuel cell repair needs.

9. J-B Weld 8272 Marineweld Marine Epoxy – 2 Oz.

J-B Weld MarineWeld is a versatile, two-part epoxy cold weld system that provides lasting repairs to multiple surfaces. This product is perfect for all DIY marine and watercraft repairs, making it a go-to for those who want to get the job done right.

The mixing process is simple – just combine the two tubes at a 1:1 ratio. After that, it takes around 4-6 hours to set and 16-24 hours to cure. Once cured, J-B Weld MarineWeld can be tapped, filled, sanded, molded, and drilled. The set and cure color is a sleek dark grey, providing an aesthetically pleasing finish.

J-B Weld MarineWeld is steel reinforced, with a tensile strength of 5020 PSI, making it highly dependable. It can withstand temperatures up to 550 degrees Fahrenheit (287 degrees Celsius). Once cured, it is waterproof and resistant to petroleum, chemical, and acid. This product retains strength above and below water, ensuring that it can handle any marine or watercraft repair.

This product is perfect for a variety of surface applications, including aluminum, fiberglass, metal, plastic/composite, and wood. It's a go-to for those who want to complete DIY projects, big or small, with confidence. J-B Weld delivers superior performance, quality, and results for the World's Strongest Bond.

10. Hy-Poxy H-455 Alumfast 6.5 Oz Rapid Cure Aluminum Putty Repair Kit

Introducing the 5 Minute Aluminum Repair Kit, a must-have for anyone in need of quick and strong repairs. This industrial and automotive repair kit can be used to repair a variety of products, including HVAC systems, radiators, engine blocks, boat hulls, and equipment.

The kit includes an aluminum-filled epoxy putty that is specially designed for non-rusting repairs. Once applied, the putty dries quickly, allowing for repairs to be completed in just 5 minutes. This means less downtime and more productivity.

The high-strength epoxy putty is made in the USA, ensuring top-quality craftsmanship and materials. It is also incredibly easy to use, making it an ideal choice for both professionals and DIY enthusiasts.

Whether you're dealing with a small crack or a more significant repair, this aluminum repair kit has got you covered. Its unique formula ensures that the repaired area will be just as strong as the original material.

Don't let broken equipment or machinery slow you down. With the 5 Minute Aluminum Repair Kit, you can quickly and easily make repairs that will last. Invest in this reliable and efficient repair solution today and get back to business in no time.

Best Epoxy For Gas Tank Repair FAQs

Are there any safety concerns when using epoxy to repair a gas tank?

Yes, there are safety concerns when using epoxy to repair a gas tank. Epoxy is a strong adhesive that can be used to repair cracks and leaks in gas tanks. However, it is important to take the necessary safety precautions when using epoxy to repair a gas tank.

Firstly, ensure that the gas tank is empty before beginning the repair process. This will help to prevent any accidents or explosions. Secondly, make sure that the area where the repair will take place is well-ventilated. Epoxy releases fumes that can be harmful if inhaled, so it is important to work in a well-ventilated area.

Additionally, wear protective gear such as gloves, safety glasses, and a respirator to protect yourself from the fumes and any potential skin contact with the epoxy.

It is also important to follow the manufacturer's instructions when using epoxy to repair a gas tank. Use the recommended amount of epoxy and allow it to cure completely before using the gas tank again.

Overall, while epoxy can be an effective solution for repairing gas tanks, it is crucial to take the necessary safety precautions to avoid any accidents or harm.

Can any epoxy be used for repairing a gas tank, or is there a specific type that is recommended?

Epoxy can be an effective solution for repairing a gas tank, but it is important to use the right type of epoxy for this task. Not all epoxies are created equal, and some may not be suitable for use with gasoline or other fuels.

When choosing an epoxy for gas tank repair, look for a product specifically designed for this purpose. These epoxies are typically formulated to be resistant to fuel and other chemicals, and they may also contain fillers or other additives to enhance their strength and durability.

It is also important to follow the manufacturer's instructions carefully when using an epoxy for gas tank repair. This may involve preparing the surface of the tank, mixing the epoxy correctly, and applying it in a precise manner.

Ultimately, using the right type of epoxy and following proper procedures can help ensure a successful gas tank repair that is both safe and effective.

Can epoxy be used to repair gas tanks made of different materials, such as plastic or metal?

Epoxy can be used to repair gas tanks made of different materials, such as plastic or metal. However, the specific type of epoxy used will depend on the material of the gas tank. For plastic gas tanks, a two-part epoxy designed for use on plastics should be used. For metal gas tanks, a two-part epoxy designed for use on metals should be used. It is important to follow the manufacturer's instructions carefully and to ensure that the area being repaired is clean and free from any debris or contaminants. It is also important to note that epoxy repairs may not be a permanent solution and may need to be re-applied over time. In addition, any repairs to a gas tank should be done by a qualified professional to ensure the safety and integrity of the tank.

How long can the repaired gas tank last if the best epoxy is used for repair?

The duration for which a repaired gas tank can last depends on various factors including the type of epoxy used, the severity of the damage, and the maintenance practices employed. However, if the best epoxy is used for the repair, it should last for a considerable period of time. High-quality epoxies are designed to withstand extreme temperatures, pressure, and chemical exposure, making them ideal for gas tank repairs.

It is important to note that even with the best epoxy, a repaired gas tank is not a permanent solution and may require replacement at some point in the future. Regular inspection and maintenance practices, such as checking for leaks and addressing any signs of damage or corrosion, can help extend the life of a repaired gas tank.

Ultimately, the longevity of a repaired gas tank will depend on various factors, and it is essential to consult with a professional mechanic or repair expert to ensure that the best epoxy is used for the repair and to determine the expected lifespan of the tank.

How long does the epoxy take to set and cure when used for gas tank repair?

The curing time for epoxy used in gas tank repair can vary depending on the product used, the ambient temperature, and the thickness of the application. Generally, most epoxy products take around 24-48 hours to fully cure and reach their maximum strength. However, some fast-curing epoxy products can set in as little as 5 minutes but still require 24 hours to fully cure.

It's important to follow the manufacturer's instructions carefully and allow the epoxy to cure completely before using the gas tank. Failure to do so can result in leaks or other issues, which can be dangerous and costly to fix.

In addition, it's important to note that epoxy may not be the best solution for all gas tank repairs. In some cases, it may be necessary to replace the tank or seek professional repair services to ensure safety and proper function.

Is it necessary to clean the gas tank thoroughly before applying epoxy for repair?

Yes, it is necessary to clean the gas tank thoroughly before applying epoxy for repair. Any dirt, rust, or debris left inside the tank can compromise the adhesion of the epoxy and lead to a failed repair. The first step in cleaning the gas tank is to remove all fuel and fumes from the tank. This can be done by draining the tank completely and allowing it to air dry for several hours. Next, the tank should be thoroughly cleaned with a solvent such as acetone or brake cleaner to remove any remaining debris or contaminants. It is important to wear protective gloves and eye gear during this process. Once the tank is clean, it should be inspected for any signs of damage or corrosion. Any areas that are pitted or severely rusted should be repaired before applying the epoxy. In summary, taking the time to properly clean and prepare the gas tank before applying epoxy will ensure a successful repair and help prevent future problems.

What are the key factors to consider when selecting the best epoxy for gas tank repair?

When selecting the best epoxy for gas tank repair, there are several key factors that you should consider to ensure that you choose the right product for the job.

Firstly, you need to check the compatibility of the epoxy with the type of gas tank you have. There are different types of gas tanks made of different materials such as plastic, steel, or aluminum, and each requires a specific type of epoxy that is compatible with the tank material.

Secondly, you need to consider the curing time of the epoxy. A fast-curing epoxy is ideal for quick repairs, but if you have more time, a slower-curing epoxy can provide a stronger bond and better sealing.

Thirdly, you need to check the temperature resistance of the epoxy. Gas tanks may be exposed to high temperatures, so it is vital to choose an epoxy that can withstand the heat and remain stable.

Fourthly, you need to consider the viscosity of the epoxy. A thicker epoxy can be easier to apply and less likely to run or drip, but a thinner epoxy can be more effective for filling small cracks or holes.

Finally, you need to consider the reputation and quality of the epoxy brand. Choose a well-known brand with a good reputation for producing reliable, high-quality products.

What are the most reliable brands of epoxy for gas tank repair?

When it comes to repairing gas tanks, choosing the right brand of epoxy is crucial for ensuring a reliable and long-lasting repair. Some of the most reliable brands of epoxy for gas tank repair include J-B Weld, Permatex, and Devcon.

J-B Weld is a popular choice among mechanics and DIY enthusiasts alike due to its strong bonding properties and resistance to gasoline, diesel fuel, and other chemicals. Their SteelStik and TankWeld products are specifically designed for repairing gas tanks and have a proven track record of success.

Permatex is another trusted brand that offers a range of epoxy products for gas tank repair, including their PermaPoxy 5-Minute Plastic Weld and Fuel Tank Repair Kit. These products are easy to use and provide a durable, long-lasting repair.

Devcon is also a reliable brand for gas tank repair, with their Plastic Welder Epoxy and 2-Ton Epoxy products being particularly popular among mechanics and DIYers. These epoxies are resistant to gasoline and other chemicals, making them ideal for repairing gas tanks.

Ultimately, the key to a successful gas tank repair is using a high-quality epoxy from a trusted brand and following the manufacturer's instructions carefully.

What are the properties of the best epoxy for gas tank repair?

The best epoxy for gas tank repair should possess certain properties to ensure a successful repair. Firstly, it should have excellent bonding strength to form a strong and durable bond with the gas tank surface. This will prevent any leaks from occurring in the future. Secondly, it should have high chemical resistance to withstand the corrosive effects of gasoline and other chemicals present in the tank. This is important to ensure that the epoxy does not break down over time and cause further damage to the tank. Thirdly, it should have a quick curing time to reduce the downtime of the tank and enable it to be used as soon as possible. Finally, it should be heat resistant to withstand the high temperatures generated by the engine and prevent the epoxy from melting or breaking down. By possessing these properties, the best epoxy for gas tank repair will provide a long-lasting and reliable solution to any gas tank leakage problems.

What is the process for applying epoxy to a gas tank for repair?

The process of applying epoxy to a gas tank for repair involves several steps. First, the gas tank should be emptied and cleaned thoroughly to remove any debris, rust or old paint. Next, the damaged area of the gas tank needs to be sanded down and the surface should be roughened up to promote adhesion. A high-quality epoxy product should be selected based on the type of gas tank material and the extent of the damage. The epoxy should be mixed according to the manufacturer's instructions and then applied to the damaged area using a brush or spatula. The epoxy should be spread evenly and allowed to dry for the recommended time. Once the epoxy is dry, the surface should be sanded down again to ensure a smooth finish. Finally, the gas tank can be painted or coated with a sealant to protect the epoxy and prevent further damage. It is important to follow all safety precautions and instructions provided by the manufacturer when applying epoxy to a gas tank.