If you’re looking for a reliable solution to fix your plastic gas tank, epoxy can be an excellent choice. Epoxy is a versatile adhesive that can bond a range of materials, including plastics. However, not all epoxy products are the same, and you need to consider several factors before making a purchase.

Firstly, the type of plastic your gas tank is made of and the type of fuel you use are crucial factors to consider. Some epoxy products may not be suitable for specific types of plastic or can break down when in contact with certain fuels. Secondly, the drying time and setting time of the product can also be crucial. Some epoxy products may take longer to dry and set than others, which may not be practical if you need to use your car.

If you’re not sure which epoxy product is best for your gas tank, some questions can help you make the right choice. For example, you may want to ask yourself whether the product is resistant to chemicals and temperature changes. You may also want to find out whether the product comes with instructions or needs special tools or equipment. Finally, you may want to check reviews of the product to see what other car owners have to say about its performance and durability.

10 Best Epoxy For Plastic Gas Tank Repair

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for filling holes and cracks in steel, wood, and some plastics while strengthening weakened metal.

|

|

||

|

2

|

The product is ideal for repairing fuel tanks.

|

|

||

|

3

|

It is ideal for repairing gas tanks.

|

|

||

|

4

|

The product is ideal for bonding and repairing plastic materials.

|

|

||

|

5

|

It is ideal for repairing leaks and cracks in pipes, tanks, and other surfaces that come into contact with water.

|

|

||

|

6

|

Ideal for bonding and filling gaps in plastic body panels and other automotive parts.

|

|

||

|

7

|

It is ideal for repairing plastic items such as car parts, toys, and household items.

|

|

||

|

8

|

This product is ideal for bonding steel surfaces and filling gaps with a strong, reinforced epoxy adhesive.

|

|

||

|

9

|

Ideal for repairing leaks and cracks in gas tanks and radiators quickly and easily.

|

|

||

|

10

|

The product is ideal for repairing plastic.

|

|

1. Por-15 Black Patch – Ultimate Metal Filler

Looking for an all-purpose patch that can handle a variety of projects? Look no further than POR-15 Patch, the ultimate solution for sealing seams, patching holes, and repairing a wide range of materials.

What sets POR-15 Patch apart is its unique formulation, which combines the power of POR-15 Rust Preventive Coating with the convenience of a tube. This means that POR-15 Patch remains flexible while working, but dries rock hard and becomes impervious to fuels and solvents. In fact, it's so tough that it may even add strength to weakened metal!

To use POR-15 Patch, simply apply it to dry surfaces only while wearing protective gloves. It dries to the touch in 4-6 hours, but full cure may take up to 96 hours depending on the thickness applied. Once dry, POR-15 Patch cannot be removed by any solvent, so it provides a permanent seal.

One of the key benefits of POR-15 Patch is that it won't absorb moisture and swell like conventional body fillers. Instead, it dries to a rock-hard finish that won't crack or chip, making it ideal for use on furniture joints, steel, wood, some plastics, fuel tanks, floor pans, and even concrete and cinder blocks.

It's worth noting that because POR-15 Patch dries to a rock-hard finish, sanding can be very difficult. Therefore, it may not be suitable for use on car exterior parts if a cosmetic finish is desired.

At POR-15, they are committed to innovation, quality control, and excellent customer service. Their unbeatable 3-step stop rust system is trusted by DIY enthusiasts and professionals alike. With POR-15 Patch, you can trust that you're getting a high-quality product that will get the job done right the first time.

2. Permatex 84334 Fuel Tank Repair Epoxy Stick – 1 Oz., Black

This two-part epoxy stick is the perfect solution for those looking to repair their metal gas tanks and containers. It is hand-kneadable and comes in a putty form for easy application. With its contrasting colored materials, it is easy to identify when thorough mixing has been achieved, ensuring optimal performance.

One of the greatest advantages of this epoxy stick is that it eliminates the need for tank removal, saving both time and money. It sticks to gasoline wet metal and forms a strong bond that is resistant to fuels and most solvents after full cure.

Once cured, the adhesive can be drilled, sanded, threaded, or filed for a smooth, seamless finish. It is a versatile solution that can be used for a variety of applications, including gas tanks and gas cans.

3. J-B Weld 8217 Tankweld Gas Tank Repair – 1 Oz.,dark Grey

J-B Weld TankWeld is a highly effective, two-part epoxy putty stick that is specifically designed to repair and rebuild various holding tanks. This hand-mixable, steel-reinforced formula is ideal for repairing fuel tanks, metal radiators, metal fuel or chemical tanks, metal housings, and stripped threads. It can also be used on surfaces such as iron, stainless steel, copper, brass, aluminum, and bronze.

This product is formulated to be chemical resistant against petroleum, hydraulic fluids, and many other harsh chemicals once fully cured. It has been certified by the NSF and is safe for contact with potable water.

J-B Weld TankWeld has a lap shear strength of 900 PSI, making it incredibly strong and durable. Once the two-part formula is kneaded together by hand, it takes only 5 minutes to set and cures in just 1 hour. The set and cure color is a dark grey that blends in well with most surfaces.

One of the best things about J-B Weld TankWeld is that it can be molded, shaped, sanded, drilled, and tapped. This makes it a versatile solution for a wide range of repair and rebuilding projects. Whether you are working on a big or small project, you can easily and confidently do it yourself with J-B Weld.

J-B Weld is known for delivering superior performance, quality, and results for the world's strongest bond. This heavy-duty epoxy and adhesive is perfect for repairing and restoring a variety of materials. With J-B Weld, you can rest assured that your repairs will be done right the first time.

4. Permatex 84145 Permapoxy Black Plastic Weld – 0.84 Fl. Oz.

This structural adhesive is a versatile and reliable solution for general purpose bonding needs. It is designed to bond a wide variety of materials, including plastics, composites, ceramics, and wood, in any combination. The adhesive forms a tough, durable bond with a permanent strength of up to 3500 PSI, making it ideal for a range of applications.

One of the key advantages of this adhesive is its fast-curing formula, which sets in just five minutes at room temperature. This allows for quick and efficient bonding, minimizing downtime and ensuring that projects can be completed efficiently.

In addition to its fast-curing properties, this adhesive is also highly effective at gap filling, with a gap filling capacity of up to 0.125 inches. This makes it ideal for bonding uneven or irregular surfaces, ensuring a strong and secure bond.

5. J-B Weld 8277 Waterweld Epoxy Putty Stick – 2 Oz., Off White

J-B Weld WaterWeld is a versatile two-part epoxy putty stick that can fix a wide range of issues, including plumbing, fuel tanks, tubs and showers, drains, pool and spa, boats, and potable water tanks. It is hand-mixable and can cure underwater, making it a valuable tool for any DIY enthusiast.

This product is certified by the NSF and is safe for contact with potable water, making it an ideal choice for repairing water tanks or pipes. It sets in just 25 minutes and cures within an hour, with an off-white color when fully set.

J-B Weld WaterWeld has a lap shear strength of 1300 PSI, which means it can withstand significant pressure and tension. It can withstand continuous temperatures of up to 300F (149C) and intermittent temperatures of 350F (176 degrees Celsius). When fully cured, it is resistant to petroleum, hydraulic fluids, and other chemicals.

This product can be applied to a variety of surfaces, including iron and stainless steel, copper and brass, aluminum and bronze, fiberglass, and plastic and PVC. With its heavy-duty epoxy and adhesive properties, J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

Whether you are fixing a small issue or tackling a big DIY project, J-B Weld WaterWeld is the perfect solution. Its strength, durability, and versatility make it a valuable addition to any toolbox.

6. J-B Weld 50139 Plastic Bonder Body Panel Adhesive And Gap Filler Syringe – Black – 25 Ml

Introducing Plasticbonder, the ultimate solution for all your adhesive needs. This quick-set, two-part urethane adhesive system provides strong and long-lasting repairs, making it suitable for use on a wide range of materials, including thermoset, carbon fiber composites, thermoplastics, coated metals, and even concrete.

For more than 40 years, Plasticbonder has been a trusted name in the industry, earning a loyal following from people who take pride in their work. With each product, they innovate to provide the world's strongest bond for your projects.

Using Plasticbonder is simple and easy. With a 1:1 mixing ratio, this adhesive sets in just 15 minutes and can be sanded after 30 minutes. What's more, it cures to a hard, permanent bond with a tensile strength of 3770 psi.

Whether you need it for indoor or outdoor use, Plasticbonder is versatile and dependable. Perfect for use on a wide range of materials, including epoxy and adhesives, plastic, composite, PVC, and more, it makes a great gap filler and dries black in color.

7. Blue Magic 16502tri Quiksteel Plastic Repair Epoxy Putty – 2 Oz.

Blue Magic is a trusted manufacturer of Adhesives, Sealants, and Tape based in the United States. Their products are designed to meet the needs of both professional and DIY enthusiasts, ensuring a reliable solution for any project.

Whether you need to repair a leaky pipe, seal a crack, or secure a broken item, Blue Magic's range of Adhesives, Sealants, and Tape has got you covered. Their products are made using high-quality materials and cutting-edge technology, ensuring durability and long-lasting performance.

Their Adhesives come in a variety of forms, including epoxy, super glue, and contact cement, providing you with options for any bonding need. Their Sealants are perfect for sealing gaps, cracks, and leaks in various surfaces, including metal, plastic, and wood. Their Tape products are versatile and can be used for packaging, insulation, and even electrical work.

Blue Magic's Adhesives, Sealants, and Tape are easy to use and provide excellent adhesion, ensuring a strong bond that can withstand various conditions and environments. Their products are also resistant to water, heat, and chemicals, making them ideal for both indoor and outdoor use.

As a reputable manufacturer, Blue Magic ensures that all their products meet the highest quality standards. They provide clear instructions and specifications for their products, giving you confidence in their performance. Additionally, their products come in different sizes and packaging options, providing you with flexibility and convenience.

8. J-B Weld 8271 Kwikweld Professional Size Steel Reinforced Epoxy Twin Pack – 10 Oz.

The J-B Weld KwikWeld Pro Size is a reliable and versatile two-part epoxy system that provides a lasting and strong repair to a range of surfaces. This product is perfect for DIY enthusiasts who want a fast-setting solution for their repair needs.

After mixing the two tubes at a 1:1 ratio, this product sets in just 6 minutes and cures in 4-6 hours. Once cured, KwikWeld can be tapped, filled, sanded, molded, and drilled. The set and cure color of this product is a dark grey.

J-B Weld KwikWeld is steel reinforced and has an impressive tensile strength of 3127 PSI. It can withstand temperatures up to 230 degrees Fahrenheit (110 degrees Celsius) and is waterproof when fully cured.

This product is suitable for a range of surface applications, including metal, plastic and PVC, wood, concrete, ceramic and tile, and fiberglass. Whether you need to repair a broken tool or fix a leaky pipe, J-B Weld KwikWeld is a dependable solution that will get the job done.

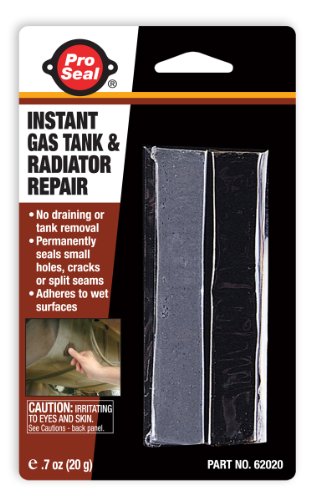

9. Super Glue Pro Seal N62020 Instant Gas Tank And Radiator Repair

The Instant Gas Tank and Radiator Repair is a reliable solution for repairing cracks and split seams in your gas tank or radiator. This repair kit comes in a convenient 0.7-ounce strip and is designed with an easy-to-use putty that can be applied in just a few simple steps.

One of the best features of this repair kit is its ability to permanently seal any cracks or split seams. Once applied, the putty hardens like steel, ensuring that your gas tank or radiator remains leak-free and in optimal condition for a long time.

The Instant Gas Tank and Radiator Repair is a versatile product that can be used on a variety of surfaces, including metal, plastic, and fiberglass. Whether you're dealing with a small crack or a larger split seam, this repair kit is more than capable of handling the job.

To use this product, simply clean the area around the crack or split seam and apply the putty in a smooth, even layer. Allow the putty to dry completely before using your gas tank or radiator again.

10. Blue Magic 16502 Quiksteel Plastic Repair Blister Card – 2 Oz.

Looking for a heavy-duty adhesive that is reliable and can withstand extreme temperatures and chemicals? Look no further than this product!

This adhesive sets in just 5 minutes and fully cures in just 1 hour, making it a fast and efficient solution for any job. Plus, it is NSF-61 certified to be safe for drinking water, giving you peace of mind in even the most sensitive applications.

With a bond that hardens like steel, this adhesive can be drilled, tapped, filed, machined, and even painted to meet your specific needs. It bonds to both wet and dry surfaces, and can even set up under water, making it ideal for use in a variety of challenging environments.

Whether you need an adhesive that can withstand high temperatures or harsh chemicals, this product has you covered. It is resistant to temperatures up to 500 degrees Fahrenheit and is impervious to a wide range of chemicals, giving you a bond that holds strong even in the toughest conditions.

And if you're worried about extreme cold temperatures, rest assured that this adhesive can handle those too. Its bond holds up even in temperatures as low as -90 degrees Fahrenheit, ensuring that it will stay strong no matter what.

Best Epoxy For Plastic Gas Tank Repair FAQs

Are there any safety precautions that need to be taken when using epoxy on a gas tank?

Yes, there are several safety precautions that need to be taken when using epoxy on a gas tank. First, it is important to ensure that the gas tank is completely empty and free of any residual fuel or fumes before applying the epoxy. This can be done by draining the tank and allowing it to air out for several hours.

Next, it is important to wear protective gear such as goggles, gloves, and a respirator to prevent any contact with the epoxy or inhalation of fumes. It is also important to work in a well-ventilated area to avoid the buildup of fumes.

When applying the epoxy, it is important to follow the manufacturer's instructions carefully and to apply it evenly and thoroughly. It is also important to allow the epoxy to fully cure before using the gas tank again, which can take several hours or even days depending on the type of epoxy used.

Overall, taking proper safety precautions when using epoxy on a gas tank is essential to prevent accidents and ensure a successful repair.

Can any epoxy be used for plastic gas tank repair?

While epoxy can be used for plastic gas tank repair, not all types of epoxy are suitable for this purpose. When selecting an epoxy for plastic gas tank repair, it is important to choose one that is specifically designed for fuel-resistant applications. These types of epoxies are formulated to withstand exposure to gasoline and other fuels without breaking down or becoming brittle.

It is also important to prepare the surface of the gas tank properly before applying the epoxy. This typically involves cleaning the surface thoroughly to remove any dirt, grease, or other contaminants that could interfere with the adhesion of the epoxy. It may also be necessary to sand the surface lightly to create a rough texture that will help the epoxy adhere more effectively.

Overall, if you are considering using epoxy for plastic gas tank repair, it is important to choose a product that is specifically designed for this purpose and to follow all of the manufacturer's instructions carefully to ensure a successful repair.

Can epoxy be used to repair cracks and holes in plastic gas tanks?

Yes, epoxy can be used to repair cracks and holes in plastic gas tanks. Epoxy is a strong adhesive that can bond with various materials, including plastics. However, before attempting to repair the gas tank with epoxy, it is important to ensure that the tank is completely drained of fuel and thoroughly cleaned. The area around the crack or hole should be sanded and cleaned to ensure proper adhesion of the epoxy. It is also important to choose an epoxy that is specifically formulated for use with plastics and fuel. It is recommended to apply multiple layers of epoxy and allow each layer to dry completely before applying the next. Once the repair is complete, it is important to allow the epoxy to cure fully before using the gas tank. It is also important to monitor the repaired area for any signs of leaks or further damage.

Can epoxy withstand gasoline and other fuel types?

Epoxy is a type of adhesive that is known for its strong and durable properties. When it comes to its ability to withstand gasoline and other fuel types, epoxy is generally resistant to these substances. However, it is important to note that not all types of epoxy are suitable for use with gasoline and other fuels.

Depending on the specific formulation and type of epoxy, it may have varying levels of resistance to different types of fuels. Some types of epoxy may be more resistant to gasoline than others, while others may be more suitable for use with diesel or other types of fuels.

If you are planning to use epoxy in an application where it will be exposed to gasoline or other fuels, it is important to choose a product that is specifically designed for this purpose. This will help to ensure that the epoxy is able to withstand the harsh chemical environment and maintain its strength and durability over time.

How long does epoxy take to cure on a plastic gas tank?

The time it takes for epoxy to cure on a plastic gas tank can vary depending on the specific type of epoxy used and the environmental conditions in which it is applied. However, in general, most epoxies will take around 24-48 hours to fully cure on a plastic gas tank.

It is important to note that curing times can be affected by factors such as temperature, humidity, and the thickness of the epoxy layer. If the temperature is too low, the curing process can be slowed down significantly. On the other hand, if the temperature is too high, the epoxy can cure too quickly, which can lead to cracking or other issues.

To ensure that the epoxy cures properly, it is important to follow the manufacturer's instructions carefully. This may involve preparing the surface of the plastic gas tank properly, mixing the epoxy components in the correct proportions, and applying the epoxy evenly and at the recommended thickness. Additionally, it is important to allow the epoxy to cure undisturbed in a controlled environment until it is fully cured.

How much epoxy is needed for a typical gas tank repair?

The amount of epoxy needed for a gas tank repair will depend on the size of the tank and the extent of the damage. As a general rule, it is recommended to use about one quart of epoxy for every 12 square feet of surface area that needs to be covered. For a typical gas tank repair, which typically involves patching small holes or leaks, a small amount of epoxy may suffice. However, for more extensive repairs, such as patching large holes or cracks, more epoxy may be needed. It is important to follow the manufacturer's instructions for mixing and applying the epoxy, as well as ensuring that the surface of the tank is clean and free from debris before application. Additionally, it is recommended to let the epoxy cure for several hours or overnight before using the tank again.

Is it safe to use epoxy on a gas tank that has had fuel in it recently?

It is not safe to use epoxy on a gas tank that has had fuel in it recently. Epoxy is a strong adhesive material that can bond to a variety of surfaces, but it is not designed to withstand the harsh chemicals found in gasoline. When gasoline comes into contact with epoxy, it can cause the adhesive to break down and dissolve, leading to a potentially dangerous situation.

If you need to repair a gas tank that has had fuel in it recently, it is best to use a specialized product designed specifically for gas tank repairs. These products are formulated to withstand the chemicals found in gasoline and can provide a safe and effective solution for repairing your gas tank.

It is also important to take proper safety precautions when working with gasoline and gas tanks. Always make sure to work in a well-ventilated area, wear protective clothing and gloves, and follow all manufacturer instructions carefully to avoid accidents or injuries.

What are the advantages of using epoxy for plastic gas tank repair?

Epoxy is a popular choice for repairing plastic gas tanks due to its numerous advantages. First and foremost, epoxy is an incredibly strong and durable material that can withstand high levels of pressure and heat, making it ideal for use in fuel tanks. It is also resistant to chemicals, including gasoline and other fuels, which means it won't break down or dissolve over time when exposed to these substances.

Another advantage of using epoxy for plastic gas tank repair is its ability to seal leaks and cracks effectively. Once applied, epoxy will fill in any gaps or holes in the tank, creating a strong, watertight seal that will prevent further leaks or damage. This can save you a significant amount of money in the long run, as you won't need to replace the entire tank or constantly repair it.

Epoxy is also relatively easy to use, even for those with little to no experience in automotive repair. Many epoxy kits come with detailed instructions that guide you through the process step-by-step, making it a simple and straightforward solution for DIY repairs.

Overall, the use of epoxy in plastic gas tank repair is an effective and practical solution that offers numerous benefits, including strength, durability, chemical resistance, and ease of use.

What is the average cost of epoxy for plastic gas tank repair?

The cost of epoxy for plastic gas tank repair can vary depending on several factors. The brand and quality of the epoxy, the size of the repair needed, and the labor costs associated with the repair can all affect the final price.

On average, a small plastic gas tank repair using epoxy can cost between $50 to $200. This price range is for a DIY repair, where you purchase the epoxy and complete the repair yourself. If you take your gas tank to a professional repair shop, the cost can be higher, ranging from $200 to $600.

It is important to note that while epoxy can be a cost-effective solution for plastic gas tank repair, it is not always a permanent fix. Depending on the extent of the damage to your gas tank, a replacement may be necessary in the long run. It is best to consult with a professional to determine the best course of action for your specific situation.

What is the best epoxy for repairing plastic gas tanks?

When it comes to repairing plastic gas tanks, it's important to choose an epoxy that is specifically designed for this application. The best epoxy for repairing plastic gas tanks is one that is both strong and resistant to gasoline and other chemicals. One of the most popular choices is the Permatex 84145 Permapoxy Black Plastic Weld. This two-part epoxy is specially formulated to bond to a variety of plastics, including polyethylene and polypropylene, which are commonly used in gas tanks. It also has excellent chemical resistance, making it ideal for use with gasoline. Another highly-rated option is the J-B Weld 8237 PlasticWeld Plastic Repair Epoxy Putty. This epoxy putty sets quickly and dries to a strong, durable finish that is resistant to chemicals and gasoline. Ultimately, the best epoxy for repairing plastic gas tanks will depend on the specific needs of your repair, as well as your personal preferences.