If you’re looking for the best inch pound torque wrench, there are several factors to consider before making your purchase. First and foremost, you'll want to consider the level of accuracy you require. Some wrenches provide accuracy within +/- 3%, while others can deliver precision down to +/- 1%. You'll also want to think about the size of the wrench, as well as its construction materials. A durable and reliable torque wrench should be able to withstand frequent use without sacrificing accuracy.

Before making your decision, it's worth considering what you'll be using the torque wrench for. If you're working with delicate electronics or tight spaces, a smaller wrench may be more appropriate. However, if you'll be using the wrench on larger pieces of machinery or vehicles, a larger model may be necessary. Additionally, some wrenches may come with added features such as reversible ratchets or different measurement units, which may influence your choice.

Are you tired of imprecise torque readings ruining your repairs or projects? Are you in need of a versatile and durable torque wrench for your workshop or garage? Look no further than these top-rated inch pound torque wrenches, specially designed for accuracy and ease of use. Keep reading to learn more about how to choose the best option for your needs and budget, and enjoy peace of mind with every project you tackle.

10 Best Inch Pound Torque Wrench

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for measuring and adjusting torque on bolts within a range of 30-250 in/lbs.

|

|

||

|

2

|

Ideal for tightening bolts and nuts on bicycles, cars, and other machinery up to 80 in/lbs or 9 N/m.

|

|

||

|

3

|

Ideal for precise tightening of bolts and nuts within a range of 20-200 in.-lb. (2.26 ~ 22.6 Nm).

|

|

||

|

4

|

The torque wrench is ideal for fastening bolts or nuts with precise torque requirements in both directions.

|

|

||

|

5

|

Ideal for accurate firearm scope mounting, gunsmithing and maintenance with adjustable torque settings and included bits and storage case.

|

|

||

|

6

|

The torque wrench is ideal for precise tightening of nuts and bolts in a range of 0-80 inch/pounds or 0-9 Newton/meters.

|

|

||

|

7

|

Ideal for measuring the amount of force applied to fasteners in the range of 0 to 75 pounds.

|

|

||

|

8

|

The torque wrench is ideal for accurately tightening bolts and nuts within a specific range of force measurement.

|

|

||

|

9

|

It is ideal for precise torque applications in the range of 20-200 in.-lb.

|

|

||

|

10

|

The torque wrench is ideal for tightening bolts to a specific torque measurement.

|

|

1. Gearwrench 3/8" Drive Micrometer Torque Wrench 30-250 In/lbs. – 85061

The newly designed torque wrench boasts a thin profile, sealed, teardrop head for improved access and durability, making it a highly effective tool for any job. With a torque accuracy of +/- 3% CW between 20% and 100% of wrench capability, this tool ensures precision and accuracy with every use.

The thin profile and sealed design of the wrench head makes it easier to reach tight spaces, allowing for more efficient and effective application. The teardrop shape of the head offers improved durability, ensuring long-lasting use for all your needs.

With the pull adjustment collar feature, making quick and easy torque setting changes has never been easier. This feature allows for seamless adjustments to be made without interrupting your work, saving you time and effort.

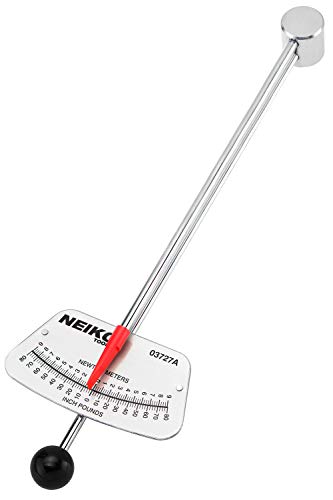

2. Versatile Neiko Wrench: Accurate Cycling & Auto Torque

Introducing the High-Precision Torque Wrench, a versatile and reliable tool that will make tightening nuts quick and easy. With its dual measurement system, this wrench offers precise readings in both standard (SAE) and metric (mm) units, eliminating the need for a conversion chart.

This quality automotive wrench is manufactured to high standards, ensuring calibration accuracy to within +/- 4%. The torque wrench reads in 0-80 in/lbs. in increments of 1 in/lb. and 0-9 Nm in 0.25 increments, providing precision on any job.

Whether you're an automobile mechanic, boat or bicycle enthusiast, or simply someone who needs to fasten nuts and bolts to the exact tightness specifications, this beam torque wrench is a must-have tool. It is designed for both left and right-handed individuals, making it a bidirectional tool that can be turned clockwise or counterclockwise. The long beam-style design makes it easy to tighten or loosen fasteners, even those in hard-to-reach places.

The High-Precision Torque Wrench is easy to use, thanks to its ball detent and chamfered ends, which hold sockets without dropping, allowing for efficient work. The ball-end handle also provides a secure, comfortable grip for smooth turning. Additionally, the wrench features large size markings that make numbers easy to read from afar, further enhancing its user-friendliness.

3. Epauto 1/4-Inch Drive Click Torque Wrench (20-200 In.-Lb. / 2.26 ~ 22.6 Nm)

The Ratchet Head is a durable and reliable tool designed to make your life easier. Made from high-quality Chrome Vanadium steel alloy (Cr-V), it has been treated with a hardening process to ensure its durability. The satin finish on the tool is corrosion-retardant, so it will last for years to come. This tool is made in Taiwan, ensuring that you are getting a product of the highest quality.

To make storage and transportation convenient, the tool comes with a sturdy plastic storage case. The knurled handle provides a non-slip grip, making it easy and comfortable to use for extended periods of time.

The high contrast and dual range scale on the tool make it easy to read, ensuring that you can always see the measurements clearly. The tool is pre-calibrated to ± 4% accuracy, so you can be sure that your measurements are always precise.

The Ratchet Head is a simple yet reliable tool that is designed to make your life easier. When you reach the preset torque value, you will hear and feel a "click" sound, telling you that it's time to stop applying force. This feature ensures that you won't over-tighten your bolts and damage your equipment.

4. Tekton 1/4 Inch Drive Dual-Direction Click Torque Wrench (10-150 In.-Lb.) | Trq21101

The 1-pc. 1/4 in. drive dual-direction torque wrench, along with a zipper case and product manual with torque conversion chart, is the perfect tool for confidently tightening fasteners to a manufacturer's torque specifications. This ensures that expensive damage caused by overstressed or poorly secured parts is prevented.

The wrench emits a clear and audible click, as well as a tactile sensation, when the preset value is reached. This feature provides a reliable and easily noticeable indication that the desired torque has been achieved.

The spring-loaded adjustment collar is smooth and precise, allowing for easy and accurate adjustment of the torque value. Once the desired torque value is set, the collar automatically locks in place, ensuring that it won't accidentally move during use.

The finely geared 72-tooth ratchet head is reversible and measures torque in both clockwise and counterclockwise directions. This makes it suitable for regular and reverse threaded fasteners, providing users with greater flexibility and ease of use.

5. Wheeler Torque Wrench: Perfect Firearm Maintenance Accessory

The FAT Wrench is an essential tool for hunters and shooters who value accuracy and reliability. Measuring 2 L x 2 W x 6.25 H inches, it offers an accuracy of +/- 2 inch/pounds up to 40 inch/pounds and 40-65 is +/- 5%. This means that you can apply repeatable and accurate torque settings to scope rings, guard screws, windage screws, and base screws, which aids in accuracy and decreases the opportunity for problems in the field.

The FAT Wrench has a torque adjustment range from 10 inch/pounds to 65 inch/pounds, making it a reliable tool for a variety of applications. Additionally, the bits are made of S2 tool steel and hardened to 56-58 Rockwell “C”, ensuring durability and strength.

Included with the FAT Wrench are 10 bits: a hex to square adapter, #10 flat blade, #32 flat blade, #11 flat blade, 5/32 hex, 7/64 hex, 3/32 hex, T20 torx, T15 torx, and Leupold specialty flat blade. The ¼” socket and a convenient plastic storage case make it easy to keep the FAT Wrench and its bits organized and accessible.

To ensure long-term use, it is recommended to always return to the lowest inch/pound setting after use. Furthermore, this product is covered by a limited lifetime warranty provided by Wheeler, guaranteeing its quality and reliability. If you ever require assistance, please contact Wheeler customer service for help.

6. High-Visibility Torque Wrench For Precision Mechanics.

The ARES 1/4-inch Drive 0-80 in/lb Beam Torque Wrench is a reliable and effective tool for various applications such as bikes, motorcycles, cars, boats, and more. It features standard and metric markings, eliminating the need for conversion while on the job. The high visibility markings make it easy to read even in tough lighting conditions, and its design allows for counter-clockwise and clockwise use.

This Beam Torque Wrench provides precision measurements from 0-80 in/lb in 2.5 in/lb increments and 0-9 Nm in .25 Newton Meter increments, ensuring accuracy within +/- 4%. Unlike other torque wrench types, the deflection beam torque wrench does not wear or fatigue over the lifetime of the tool, which guarantees increased accuracy.

The ARES 1/4-inch Drive 0-80 in/lb Beam Torque Wrench is manufactured to exacting standards, which assures its quality and precision. Users trust ARES to be quality tools, and they are backed by the Performance Assurance program. If there are any issues with the product, customers can contact customer service for troubleshooting help, parts, replacement, or refund.

Additionally, the ARES brand is proud to be part of the ASPCA Business Ambassador Program, which supports the welfare of pets. With every purchase of this product, customers are also contributing to the support of this great organization.

7. Cdi Torque 751ldin Dial Indicating Torque Wrench, 1/4" Drive, Dual Scale, 0" To 75" Lbs.

The torque wrench being described boasts an impressive torque range of 0 to 75-inch pounds, making it suitable for a variety of applications. It also features a unique memory needle, which retains the maximum torque reading for efficient and accurate use.

This particular torque wrench has been thoughtfully crafted for use in a range of industries, including automotive, nuclear, and industrial markets, as well as military installations around the globe. Its sturdy torsion beam design ensures both long life and accuracy, making it an ideal addition to any toolkit.

Additionally, the wrench is equipped with an easy-to-read laser marked single scale, allowing for clear and precise measurements. Overall, this torque wrench is a reliable and functional tool that is sure to meet the needs of professionals and hobbyists alike.

8. Etork Click-Style Torque Wrench (3/8-Inch Drive) (Range: 50-250 Inch Pounds / 6-28 Newton Meters)

This torque wrench comes with a lifetime personal use guarantee, giving the user peace of mind knowing that they are investing in a product that will last. The wrench is designed to click and/or release when the preset torque value is reached, making it easy to use and preventing over-tightening.

With its accuracy of +/- 3% in the clockwise direction, it outperforms most of its competitors who have an accuracy of +/- 4%. This ensures that the user can trust the precision of the tool and rely on it for accurate measurements.

Notably, this torque wrench is capable of measuring torque in both the clockwise and counterclockwise directions, making it versatile and suitable for a wide range of applications. This feature ensures that it can be used for both tightening and loosening nuts and bolts.

9. Tekton 1/4 Inch Drive Micrometer Torque Wrench (20-200 In.-Lb.) | 24320

The 1/4 in. drive torque wrench set is an essential tool for any mechanic or DIY enthusiast. This set includes a 1-pc torque wrench, a storage case, and a product manual with a torque conversion chart.

The torque wrench emits a distinct click that can be both heard and felt when the preset value is reached, ensuring precise and accurate tightening of bolts and nuts. The high-contrast dual-range scale is permanently marked and easy to read, even in low light conditions, making it effortless to monitor the torque values.

The ratchet head is reversible, making it suitable for driving in both directions, and measures torque in the clockwise direction. This versatile feature makes it a great tool for a wide range of applications.

The torque wrench is constructed with durable all-steel, ensuring long-lasting use. Unlike other torque wrenches, this set is free of plastic parts that can break or wear out over time, providing a reliable and sturdy tool.

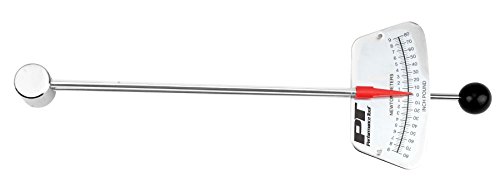

10. Performance Tool M195 0-80 In/lb & 0-7 Newton-Meter Beam Style Torque Wrench

Introducing the 1/4'' Drive Torque Beam Wrench, the perfect tool for all your precise torque measurement needs. With a range of 0-80 in/lbs., this wrench provides accurate clockwise or counterclockwise measurement, making it a versatile addition to any toolkit.

The ball type handles on this wrench are designed to localize force in order to ensure greater accuracy when measuring torque. This means that you can trust this tool to provide consistent and reliable results every time you use it.

Unlike traditional torque wrenches which can wear or fatigue over time, the deflection beam wrench technology used in this tool is designed to last a lifetime. This means that you can rely on this wrench to maintain its accuracy, even after years of use.

With the ability to directly measure a variety of torque values when tightening fasteners, this wrench is a must-have for anyone who needs to ensure that their fasteners are tightened to the correct specifications. Whether you're a professional mechanic or a DIY enthusiast, this tool is sure to make your life easier and more efficient.

Best Inch Pound Torque Wrench FAQs

Are click-type or beam-type inch pound torque wrenches more precise?

Both click-type and beam-type inch pound torque wrenches are precise measuring tools, but they have their own advantages and limitations.

Click-type torque wrenches are more commonly used in the industry due to their accuracy and ease of use. This type of wrench has a mechanism that produces an audible click sound when the pre-set torque value is reached, indicating that the desired torque has been achieved. This allows the user to stop tightening the bolt or nut at the precise moment, preventing over-tightening which could lead to damage or failure of the part.

On the other hand, beam-type torque wrenches use a calibrated beam that deflects under load to indicate the torque value. They don't have a clicking mechanism, but they provide a visual indication of how much torque is being applied. They do require more skill to use than click-type wrenches, as the user has to carefully observe the deflection of the beam to determine the torque value.

In summary, both types of inch pound torque wrenches are precise, but click-type wrenches are more user-friendly and commonly used in the industry due to their accuracy and ease of use.

Are digital or analog inch pound torque wrenches more accurate?

Both digital and analog inch pound torque wrenches can provide accurate torque measurements, but each has its advantages and disadvantages.

Analog torque wrenches use a mechanical spring to measure torque, while digital torque wrenches use electronic sensors. Analog wrenches are generally more durable and can be used in harsher environments, but they require more frequent calibration to maintain accuracy. Digital wrenches are often more precise and easier to read, but they can be more fragile and require more care in handling.

Ultimately, the accuracy of a torque wrench depends on several factors, including the quality of the wrench, the calibration process, and the user's technique. It's important to choose a reputable brand and follow the manufacturer's instructions for calibration and use to ensure accurate torque measurements.

In summary, both types of inch pound torque wrenches can provide accurate results, but the choice between them will depend on the user's specific needs and preferences.

Can a 1/4 inch drive torque wrench accurately measure inch pounds?

Yes, a 1/4 inch drive torque wrench can accurately measure inch pounds. The key is to ensure that the torque wrench is calibrated for inch pounds rather than foot pounds. Most torque wrenches have a scale that allows you to switch between units of measure. It is important to select the appropriate unit of measure before using the torque wrench.

Additionally, it is important to use the torque wrench properly to ensure accurate measurements. This includes setting the torque wrench to the desired torque value, ensuring that the wrench is properly aligned with the fastener, and applying a slow, steady force to the handle.

It is also important to note that different torque wrenches have different levels of accuracy. Higher quality torque wrenches typically have a tighter tolerance and are able to provide more consistent and accurate measurements. It is always a good idea to consult the manufacturer's instructions and specifications to ensure that you are using the torque wrench correctly and obtaining accurate measurements.

Can an inch pound torque wrench be used for tightening bicycle components?

Yes, an inch-pound torque wrench can be used for tightening bicycle components as long as it has the appropriate range and settings. An inch-pound torque wrench is designed to measure torque in inch-pounds, which is a common unit of measurement in the bicycle industry. Many bicycle components, such as stem bolts, seatpost bolts, and derailleur hanger bolts, have torque specifications in the range of 5-15 inch-pounds.

It is important to note that not all inch-pound torque wrenches are created equal. Some may have a range that is too high or too low for bicycle components, and some may not have the necessary settings or accuracy. It is recommended to use a torque wrench that is specifically designed for bicycles or one that has settings that can be adjusted to the appropriate range.

Using a torque wrench to tighten bicycle components is important for ensuring proper installation and preventing damage or failure. Over-tightening can lead to stripped threads or component failure, while under-tightening can result in components coming loose during use. By using a torque wrench, you can achieve the correct torque specifications and ensure the safety and longevity of your bicycle components.

Can an inch pound torque wrench be used for tightening delicate electronic components?

An inch pound torque wrench is typically used for tightening bolts and nuts that require a specific amount of torque, which is usually measured in inch-pounds. However, when it comes to delicate electronic components, it is not recommended to use an inch pound torque wrench.

Electronic components are fragile and sensitive to pressure, and applying too much torque can damage or break them. Instead, it is recommended to use a hand tool with a sensitive touch or a torque screwdriver that is specifically designed for delicate electronic components. These tools have adjustable torque settings that are much lower than those of an inch pound torque wrench, allowing for precise and gentle tightening.

It is important to follow the manufacturer's recommendations and use the appropriate tools for the job to avoid damaging the delicate electronic components. If you are unsure about which tool to use, consult with a professional or seek guidance from the manufacturer.

How often should an inch pound torque wrench be calibrated?

An inch pound torque wrench is an essential tool that is commonly used in various industries such as automotive, aerospace, and manufacturing. It is crucial to ensure that the tool is accurate and reliable to avoid any safety hazards or product defects. As a general rule, an inch pound torque wrench should be calibrated at least once a year or after 5,000 cycles of use, whichever comes first. However, it is worth noting that the calibration frequency may vary depending on the manufacturer's recommendations and the level of usage. It is always advisable to follow the manufacturer's guidelines and regularly inspect the tool's condition to identify any signs of wear and tear or damage that may affect its accuracy. In conclusion, regular calibration and maintenance of an inch pound torque wrench are essential to ensure its accuracy and prolong its lifespan.

What is the best inch pound torque wrench for automotive use?

When it comes to automotive use, having a reliable and accurate inch pound torque wrench is crucial for ensuring the safety and performance of your vehicle. There are several options available on the market, but the best one will depend on your specific needs and budget.

One highly recommended option is the CDI Torque 1/4-Inch Drive Adjustable Micrometer Torque Wrench. This torque wrench features a durable all-steel construction and an easy-to-read micrometer scale for precise torque settings. It also has a comfortable grip and a quick-release button for easy socket changes.

Another great option is the Tekton 1/4-Inch Drive Click Torque Wrench. This wrench has a reversible ratcheting head and an audible click that signals when the desired torque is reached. It also has a high-contrast dual range scale and a durable all-steel construction.

Ultimately, the best inch pound torque wrench for automotive use will be one that is reliable, accurate, and suits your specific needs and preferences. It is important to do your research and invest in a quality tool that will last for years to come.

What is the difference between an inch pound torque wrench and a foot pound torque wrench?

The difference between an inch pound torque wrench and a foot pound torque wrench lies in the units of measurement they use to express the amount of torque applied. An inch pound torque wrench is designed to measure torque in inch-pounds, which is a unit of force applied at a perpendicular distance of one inch from the point of rotation. On the other hand, a foot pound torque wrench measures torque in foot-pounds, which is a unit of force applied at a perpendicular distance of one foot from the point of rotation.

The choice between an inch pound and a foot pound torque wrench depends on the application and the level of precision required. Inch pound torque wrenches are typically used for smaller, more delicate applications that require finer adjustments and greater precision, such as electronics and small machinery. Foot pound torque wrenches, on the other hand, are used for larger, more heavy-duty applications that require higher levels of torque, such as automotive and industrial machinery.

In conclusion, the main difference between an inch pound torque wrench and a foot pound torque wrench is the unit of measurement they use to express the amount of torque applied.

What is the maximum torque capacity of the best inch pound torque wrenches?

The maximum torque capacity of the best inch pound torque wrenches can vary depending on the specific model and brand. However, generally speaking, the highest quality inch pound torque wrenches on the market can have maximum torque capacities that range from around 10 inch pounds up to 200 inch pounds or more. It's important to note that different types of torque wrenches may have different maximum torque capacities, so it's crucial to choose the right tool for the job. Additionally, it's important to use the torque wrench properly and to follow the manufacturer's instructions to ensure accurate and safe torque application. Investing in a high-quality inch pound torque wrench can be a great choice for those who frequently work with small bolts and fittings where precise torque is crucial for proper assembly and safety.

What is the most reliable brand of inch pound torque wrench?

When it comes to selecting the most reliable brand of inch pound torque wrench, there are several options available in the market. However, one of the most reputed and dependable brands is the CDI Torque Products. They are known for their high-quality and accurate torque wrenches that are specifically designed for professional use. Their products are made from durable materials, offer excellent precision, and come with a wide range of features that make them easy to use.

Another dependable brand is the Snap-On Torque Wrench. This brand is widely recognized for its high accuracy and consistent performance. They offer a range of torque wrenches that are designed to meet the needs of different professionals. Their products are easy to use and come with a variety of features that make them suitable for different applications.

Other reliable brands of inch pound torque wrenches include Proto, GearWrench, and Precision Instruments. These brands are also known for their high-quality and dependable products that offer excellent precision and durability. Ultimately, the most reliable brand of inch pound torque wrench will depend on your specific needs and preferences.