If you’re looking for the right metal cutting sawzall blades, you will quickly realize that there are numerous options available in the market. However, it’s essential to invest in blades that will meet your metal cutting needs and last long. Before buying blades, consider the thickness, hardness, and type of material you intend to cut. Blade thickness translates to durability and determines the type of material the blade can cut, while the hardness determines the blade's lifespan and heat resistance. Additionally, the blade's type varies in the number of teeth and TPI, affecting the speed and smoothness of cuts.

Cutting metal can be a challenging task, so you need to ask yourself a few questions before choosing the best metal cutting sawzall blades. Are you looking for blades that cut through thick metal sheets quickly? Do you prefer blades that create smooth cuts? Are you concerned about the blade's durability? Do you need blades that can remain sharp even after multiple uses? Answering these questions will guide you in choosing blades that meet your needs. Additionally, looking through customer reviews can provide valuable insights into the blade's reliability, performance, and value for money.

Investing in high-quality metal cutting sawzall blades can go a long way in making your work easier and reducing frustration. By considering the factors mentioned above and asking the right questions, you can choose blades that will make your metal cutting tasks easier and more efficient.

10 Best Metal Cutting Sawzall Blades

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

It is ideal for cutting metal with its 14 teeth per inch and pack of 25 blades.

|

|

||

|

2

|

It is ideal for cutting thick metal with its 10 TPI blades in a pack of 25.

|

|

||

|

3

|

The product is ideal for metal cutting in tight spaces and making precise cuts.

|

|

||

|

4

|

The product is ideal for cutting through thick metal with its 8/10 TPI Edge Reciprocating Saw Blades.

|

|

||

|

5

|

Ideal for cutting metal with precision, efficiency and durability using a reciprocating saw.

|

|

||

|

6

|

Ideal for cutting thick metal with reciprocating saws.

|

|

||

|

7

|

The product is ideal for cutting through a variety of materials with a reciprocating saw.

|

|

||

|

8

|

Ideal for heavy metal cutting with a reciprocating saw.

|

|

||

|

9

|

The product is ideal for cutting through a range of materials including metal and wood.

|

|

||

|

10

|

Ideal for metal cutting with reciprocating saws, offering 18 teeth-per-inch and comes in a pack of 25 blades.

|

|

1. Irwin Reciprocating Saw Blades, Metal Cutting, 6-Inch, 14 Tpi, 25-Pack (372614b)

This cutting-edge product is designed to provide a seamless cutting experience for all metal types. The electronic beam weld is an innovative feature that enhances the strength and durability of the teeth, ensuring a longer lifespan. The teeth are crafted with 8% cobalt, which keeps them sharp for longer, increasing their overall effectiveness.

The bi-metal construction of this product is another great feature, as it allows for faster cutting and added durability. The precision-set teeth are designed to provide faster, smoother cuts, making this product a go-to for all your metal cutting needs.

This versatile tool can cut through a wide range of metals, including non-ferrous pipe conduit, stainless steel, and sheet metals. Whether you're working on a DIY project or a professional job, this product is sure to meet your needs.

This cutting tool is optimized for materials ranging from 1/8 to 1/2 inch thick (3.2 to 13 mm), ensuring that it can handle a wide range of materials with ease. Its innovative design and construction make it an excellent choice for anyone looking for a reliable and efficient metal cutting solution.

2. Lenox Gold Metal Blades: 9" 25-Pack.

The LENOX reciprocating saw blades are a must-have for anyone looking to enhance their cutting game. With a design that delivers up to 2 times longer life compared to traditional straight blades, these blades are a game-changer. The aggressive curved blade design optimizes the angle of attack, resulting in faster cutting in various materials.

Featuring T2 technology and a precision-applied Titanium Nitride coating, these blades can dissipate heat, thus extending their lifespan. This unique combination of features provides for a durable and reliable blade that can withstand the most demanding cutting applications.

These blades are available in multiple variations to suit different cutting needs. Whether you are cutting wood, metal, demolition, or heavy metal, there is a blade option that will work for you. The 10 tooth per inch blades are perfect for thick metals, metal demolition, fire, and rescue.

With their origin in the USA, the LENOX reciprocating saw blades are produced with global components, ensuring their top-notch quality. Whether you are a professional contractor or a DIY enthusiast, these blades are a must-have in your toolbox.

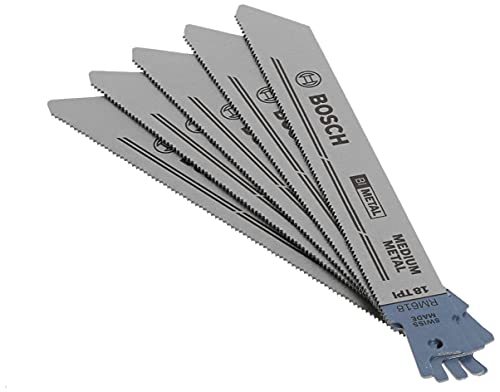

3. Bosch Rm618 6-Inch 18t Metal Cutting Reciprocating Saw Blades – 5 Pack , Blue

Looking for high-quality power tools and accessories? Look no further than this Swiss-made package that is sure to impress any DIY enthusiast or professional. With package dimensions of 22.275 H x 1.676 L x 5.994 W (centimetres), this package is compact and easy to store, while still containing everything you need for your next project.

Weighing in at just 0.086 kilograms, this package is lightweight and won't weigh you down when you're on the go. Plus, with a country of origin in Switzerland, you can be confident that you are getting a product that is made with the highest standards of quality and craftsmanship.

Whether you're a seasoned pro or just starting out, this power tool and accessory package has everything you need to get the job done right. So why wait? Order yours today and experience the difference for yourself!

4. Bosch Resm6x2 5 Pc. 6 In. 8/10 Tpi Edge Reciprocating Saw Blades For Thick Metal, Gold

Introducing the 6 In. 8/10 TPI Bi-Metal Blade, a cutting-edge tool that promises to revolutionize the way you cut through thick metal. Equipped with Turbo-Teeth technology, this blade lasts up to 3X longer than standard reciprocating saw blades, making it an excellent investment for those looking for a durable and long-lasting blade.

Engineered for extreme cuts, this blade delivers excellent cuts during high-performance applications. Whether you're a professional or a DIY enthusiast, this blade is sure to meet your needs and exceed your expectations.

One of the standout features of this blade is its precision ground blade, which starts sharp and stays sharper. This ensures that you achieve a clean and precise cut every time, without having to worry about the blade dulling or becoming less effective over time.

To ensure reliable performance, this blade is Swiss-made and constructed with premium materials. This means that you can trust this blade to deliver consistent and high-quality results, no matter what your cutting needs may be.

5. Power Blast Bi-Metal Reciprocating Saw Blade

This product boasts a bi-metal construction that enhances durability and extends the lifespan of the blade. With Power Blast Technology, this blade is strengthened to reduce breaks, ensuring longevity and reliability. This versatile blade is designed to easily cut through thin and medium metals, making it perfect for a variety of cutting tasks. Its T2 Technology allows for efficient cutting through an extensive range of materials, making it a go-to tool for professionals and DIY enthusiasts alike.

The blade features precision milled teeth that ensure smooth and precise cuts every time. The teeth are shatterproof and shock-resistant, providing added safety during usage. The high heat and wear-resistance of this blade make it an excellent choice for heavy-duty applications.

Incorporating this blade into your toolkit will increase productivity and efficiency, allowing you to complete tasks with ease and precision. Its high-quality construction ensures that it can withstand tough conditions and provide reliable performance for years to come.

6. Diablo Ds0908cf 9" Steel Demon Carbide Recip Blade For Thick Metal Cutting

This high-performance carbide single blade is a must-have tool for tackling tough metal cutting tasks. Equipped with enhanced carbide tip, this blade offers superior durability and cutting performance in metals ranging from 3/16" to 9/16" thickness. The enhanced carbide tip to blade connection ensures extreme impact resistance, making it an ideal choice for heavy-duty applications.

The blade's oversized 1 inch body ensures straighter cuts with minimal vibration, resulting in clean and precise cuts every time. This single blade is imported, ensuring top-notch quality and exceptional performance.

Whether you are a DIY enthusiast or a professional metal worker, this high-performance carbide single blade is a reliable and efficient tool for all your metal cutting needs. Invest in this single blade today and experience the difference in performance and durability.

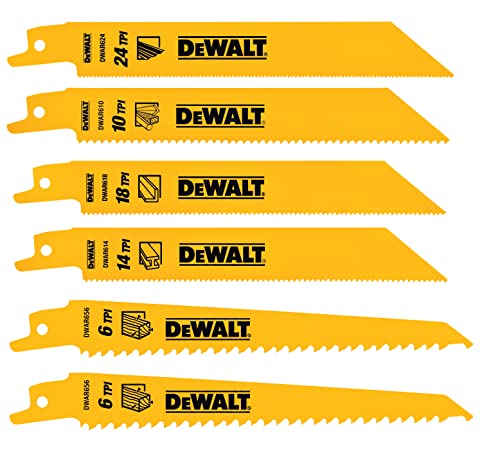

7. Dewalt Reciprocating Saw Blades, Straight Back, 6-Inch, 14 Tpi, 5-Pack (Dw4808)

This reciprocating saw blade by DEWALT is designed to optimize chip removal for efficient cutting and a longer lifespan. In fact, it boasts up to 50% longer life than previous DEWALT blades due to its patented toothforms. The tooth design utilizes sharper geometry for faster cut rates, while an aggressive shank angle increases tooth contact, allowing the blade to maintain cutting speed even as it wears down.

Constructed with bi-metal, this blade is flexible and has a long-lasting cutting edge, making it a durable option for heavy-duty cutting tasks. Additionally, it features a specially formulated anti-stick coating that minimizes friction and gum-up, resulting in smoother cuts.

This product is proudly made in the U.S.A. with global materials, ensuring a high level of quality and craftsmanship. With a 1/2-inch diameter, it is suitable for a variety of cutting applications.

8. Ezarc Cobalt Sabre Saw Blades: Tough Metal Cutting (5-Pack)

The Cobalt Teeth Sawzall Blade is a top-of-the-line demolition tool that is specifically designed for cutting through heavy metals with ease. Its M42 cobalt teeth are highly resistant to heat, making it ideal for use on the toughest of jobs.

The Metal Master technology features a hard cobalt edge that effortlessly cuts through sheet metal, metal pipes, and profiles. This makes it perfect for use in metalworking and other industrial settings.

The blade's optimized design provides superior wear resistance, ensuring a longer lifespan and better performance. It is specifically designed for cutting through medium-thick sheet metals ranging from 3 to 10mm, as well as metal pipes and profiles with a diameter of less than 100mm.

The Cobalt Teeth Sawzall Blade features a universal 1/2 inch shank that fits all Sawzall tools on the market, including those from Bosch, Dewalt, Milwaukee Sawzall Saw, SKIL, Makita, Black & Decker, Ryobi, Porter Cable, Hitachi, Flex, Hilti, Metabo, and more. This makes it a versatile and reliable tool that can be used for a variety of applications.

9. Dewalt Reciprocating Saw Blades, Metal/wood Cutting Set, 6-Piece (Dw4856)

Introducing the DEWALT Reciprocating Saw Blade, the ultimate tool for heavy metal cutting and demolition applications. With its patented tooth forms, this blade is designed to optimize chip removal for efficient cutting and long life. In fact, on average, it can last up to 50% longer than prior generation DEWALT blades, making it a reliable and cost-effective choice for professionals and DIY enthusiasts alike.

One of the standout features of this blade is its tall, thick profile. This design allows it to make straight cuts even in the toughest metal cutting applications, while also adding durability for demanding demolition tasks. You can trust that this blade will not only get the job done, but it will also hold up to the wear and tear of heavy-duty use.

The DEWALT Reciprocating Saw Blade is also constructed with bi-metal for added flexibility and a long-lasting cutting edge. This material is known for its durability and ability to withstand high-impact applications, making it a top choice for professionals in the construction and demolition industries.

This blade is proudly made in the USA with global materials, ensuring that you are getting a high-quality product that has been manufactured to the highest standards. The ToughCase Container that houses the blade is made in China, but the blade itself is crafted with the utmost care and precision in the USA.

10. Lenox Tools Reciprocating Saw Blades, Metal Cutting, 6-Inch, 18 Tpi, 25-Pack (20494b614r)

This cutting edge product boasts bi-metal construction, ensuring its durability and longevity. The blade's strength is fortified by the innovative Power Blast Technology, which minimizes the risk of breaks. This versatile blade is specifically designed to cut through thin and medium metals with ease. Thanks to T2 Technology, it can also cut through an extensive range of materials with efficiency and precision.

The blade is fortified with an 8% cobalt edge, making it even more resilient and reliable. Its shatterproof, precision-milled teeth further enhance its durability, allowing it to withstand the toughest conditions. The blade is highly wear-resistant, providing exceptional value for money.

Whether you're a professional tradesperson or tackling a DIY project, this bi-metal blade is an essential addition to your toolkit. With its impressive parameters and specifications, you can be confident that you'll achieve precise and efficient cuts every time. Don't settle for a subpar blade – invest in this top-quality product for unparalleled performance and durability.

Best Metal Cutting Sawzall Blades FAQs

Can I use a general-purpose sawzall blade for cutting metal, or do I need a specific blade?

While a general-purpose sawzall blade can be used for cutting metal, it is not recommended. This is because the blade is designed for cutting wood and other soft materials, and may not have the necessary strength or durability to cut through metal effectively.

If you are looking to cut through metal, it is important to invest in a blade specifically designed for that purpose. Metal cutting blades are made from high-speed steel or carbide, which allows them to withstand the heat generated by cutting through metal. Additionally, they have a different tooth design that is optimized for cutting through metal, providing a cleaner and more efficient cut.

When choosing a metal cutting blade for your sawzall, consider the thickness and type of metal you will be cutting. Thicker metals may require a blade with fewer teeth per inch (TPI), while thinner metals may require a blade with more TPI. It is also important to follow the manufacturer's instructions for blade installation and use to ensure the best results and avoid injury.

How do I avoid overheating and damaging metal cutting sawzall blades?

Overheating and damaging metal cutting sawzall blades is a common problem that can lead to reduced blade life and damage to the saw. There are a few things you can do to avoid this problem. Firstly, make sure that you are using the right blade for the job. Blades that are designed for cutting thicker metals will be more durable and less prone to overheating. Secondly, make sure that you are using the right speed and pressure when cutting. Cutting too fast or applying too much pressure can cause the blade to overheat and wear out quickly. You should also make sure that the blade is properly lubricated to reduce friction and heat buildup. Finally, take breaks when cutting to allow the blade to cool down and prevent overheating. By following these tips, you can avoid overheating and damaging your metal cutting sawzall blades and ensure that they last longer and perform better.

How do I choose the right tooth count for a metal cutting sawzall blade?

Choosing the right tooth count for a metal cutting Sawzall blade is crucial for achieving the desired result. The tooth count determines the speed, smoothness, and accuracy of the cut. The general rule is that the fewer teeth a blade has, the faster it will cut through the material, but the rougher the cut will be. On the other hand, a blade with more teeth will produce a smoother cut but will take longer to cut through the material.

For a metal cutting Sawzall blade, tooth count typically ranges from 14 to 24 teeth per inch. If you are cutting thin metal, a blade with a higher tooth count will be ideal. A 24 TPI blade will produce a smooth cut on thin metal, but it will take longer to cut through thicker metal. For thicker metal, a blade with a lower tooth count, such as a 14 TPI blade, will be more suitable for faster and rougher cuts.

In conclusion, selecting the right tooth count for a metal cutting Sawzall blade depends on the thickness of the material and the desired cut quality. Always refer to the manufacturer's recommendations and specifications for the tool and the material being cut for best results.

How long do metal cutting sawzall blades typically last?

The lifespan of a metal cutting sawzall blade can vary depending on several factors. One of the most significant factors is the type of material being cut. Harder metals such as steel and iron tend to wear down blades faster than softer metals such as aluminum. Another factor is the thickness of the material being cut. Thicker materials will require more force and may wear down the blade quicker.

On average, a metal cutting sawzall blade can last between 20 to 50 cuts, but this can vary depending on the factors mentioned above and the quality of the blade. Higher quality blades made from materials such as carbide can last significantly longer than lower quality blades.

It's essential to keep an eye on the blade's condition and replace it when it becomes dull. Continuing to use a dull blade can lead to slower cutting times, overheating, and potentially dangerous situations. Overall, it's best to invest in high-quality blades and follow proper maintenance procedures to ensure the longest lifespan possible.

What are the best materials for metal cutting sawzall blades?

When it comes to selecting the best materials for metal cutting Sawzall blades, there are a few options to consider. The most common materials for Sawzall blades are high-speed steel (HSS), bi-metal, and carbide.

HSS blades are a good middle-of-the-road option as they are affordable and can handle cutting through a variety of metals. However, they may dull quickly with heavy use and high temperatures.

Bi-metal blades are made with two types of metals, typically HSS and a more durable material like cobalt. They are designed to be durable and long-lasting, making them a good choice for heavy-duty metal cutting.

Carbide blades are the most durable and long-lasting option, as they are made with a hard, wear-resistant material. They can handle cutting through tough metals like cast iron and stainless steel, but they are also the most expensive option.

Ultimately, the best material for your metal cutting Sawzall blade will depend on the specific type of metal you are cutting and the frequency of use. It's important to consider the durability, cost, and versatility of each material before making a decision.

What is the best technique for cutting thick metal with a sawzall?

When it comes to cutting thick metal with a sawzall, there are a few techniques that can be used to ensure a successful and efficient cut. First and foremost, it is important to choose the right blade for the job. Look for a blade specifically designed for cutting metal, with a high tooth count and a bi-metal construction for durability.

Next, it is important to let the saw do the work. Don't force the blade through the metal, as this can cause the blade to bind or break. Instead, use a slow and steady motion, allowing the saw to cut through the metal at its own pace.

Another technique that can be helpful is using a lubricant, such as cutting oil or WD-40, to reduce friction and heat buildup. This can prolong the life of the blade and make the cutting process smoother.

Finally, it is important to wear appropriate safety gear, such as gloves, eye protection, and ear protection, as cutting through thick metal can be a noisy and potentially dangerous process. By following these techniques, you can achieve a clean and accurate cut through even the thickest metal with a sawzall.

What is the best way to lubricate metal cutting sawzall blades?

The best way to lubricate metal cutting sawzall blades is by using a lubricant specifically designed for cutting metal. There are many options on the market, but one of the most popular is a spray lubricant like WD-40. When using a spray lubricant, it is important to apply it evenly and generously to the blade before each use. This will help to reduce friction, which can cause the blade to overheat and wear out more quickly. Additionally, it is important to clean the blade after each use to remove any debris or buildup that may have accumulated during cutting. A clean and lubricated blade will not only last longer but will also provide a smoother and more efficient cutting experience. It is important to note that using the wrong type of lubricant or failing to properly lubricate the blade can result in damage to the blade or even injury to the user, so it is important to follow manufacturer recommendations and safety guidelines.

What is the difference between bi-metal and carbide tipped sawzall blades for metal cutting?

Bi-metal and carbide tipped sawzall blades are both commonly used for cutting metal, but they differ in terms of their composition and cutting capabilities.

Bi-metal blades are made from two different metals, typically high-speed steel and a more flexible material like spring steel. This combination provides the blade with the ability to flex and bend during cutting, making it less likely to break. Bi-metal blades are best suited for cutting softer metals like aluminum and copper, as well as wood and plastics.

Carbide tipped blades, on the other hand, are made from a combination of tungsten carbide grains and a metal binder. This results in a much harder and more durable blade that is ideal for cutting harder metals like stainless steel and cast iron. Carbide tipped blades also tend to last longer than bi-metal blades due to their superior hardness.

In summary, bi-metal blades are best for softer metals and general purpose cutting, while carbide tipped blades are better suited for harder metals and more heavy-duty cutting applications.

What safety precautions should I take when using metal cutting sawzall blades?

When using metal cutting sawzall blades, it is important to take certain safety precautions to prevent any accidents or injuries. Firstly, make sure that you are wearing the appropriate personal protective equipment (PPE), including eye protection, gloves, and ear protection. These will help prevent any injuries from flying debris or loud noises.

Before using the sawzall, inspect the blade to ensure that it is not damaged or dull. A damaged or dull blade can cause the saw to kick back or break, which can be dangerous. When cutting, make sure that the workpiece is secure and stable, and that you are not cutting above your head or in an awkward position.

Always use the proper blade for the material you are cutting, as using the wrong blade can damage the saw or cause the blade to break. Additionally, avoid cutting through nails or other hard materials that may damage the blade or cause it to break.

Finally, always unplug the sawzall before changing the blade or performing any maintenance. By following these safety precautions, you can ensure a safe and successful cutting experience with your metal cutting sawzall blade.

Which brand makes the best metal cutting sawzall blades?

When it comes to metal cutting sawzall blades, there are several brands that offer high-quality options. However, some of the best brands in the market include Milwaukee, Diablo, and Lenox.

Milwaukee is a well-known brand in the industry and is known for producing durable and efficient metal cutting sawzall blades. Their blades are designed with a unique tooth shape that enhances the cutting speed and accuracy. Additionally, Milwaukee blades are made of high-quality steel and have an optimized tooth geometry that enhances the blade's performance.

Diablo is another brand that produces some of the best metal cutting sawzall blades. Their blades are designed with carbide teeth that are capable of cutting through tough materials like steel, cast iron, and alloys. Additionally, Diablo blades have a Perma-SHIELD coating that protects against heat, gumming, and corrosion.

Lenox is also a reputable brand that produces high-quality metal cutting sawzall blades. Their blades are designed with T2 technology that enhances the blade's durability and performance. Additionally, Lenox blades have a unique design that reduces friction, enhances speed, and increases the blade's lifespan.

Overall, when it comes to metal cutting sawzall blades, choosing a reputable brand like Milwaukee, Diablo, or Lenox can ensure that you get a high-quality and reliable product.