If you’re looking for the best mold material for casting resin, there are some factors to consider before buying. First and foremost, you need a mold material that won’t stick to the resin, so a non-stick surface is important. Second, the mold should be able to withstand the heat and pressure of the curing process so as not to deform or break. Finally, the mold should be easy to work with, either by pouring or brushing on the mold material.

When it comes to mold material options, there are several to choose from, including silicone, rubber, and plastic. Silicone molds are popular because they’re non-stick and flexible, making it easy to remove the cured resin without damaging the mold or the cast. Rubber molds, on the other hand, are more durable and can be used multiple times, but are typically more difficult to remove the cast from. Plastic molds are also an option, but they’re not as flexible as silicone or rubber and may not last as long.

If you’re wondering how to choose the right mold material for your specific project, here are some questions to ask yourself. What type of object are you casting? Is it intricate and detailed, requiring a flexible mold material? Or is it simple and straightforward, allowing for a more durable mold material? How many casts do you need to make? Will you need to pour or brush on the mold material? By answering these questions, you can narrow down your options and find the best mold material for your resin casting needs.

10 Best Mold Material For Casting Resin

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for creating molds for resin and silicone DIY projects.

|

|

||

|

2

|

This product is ideal for making molds out of liquid silicone rubber for casting and creating resin or silicone products.

|

|

||

|

3

|

Making strong, reusable silicone molds, suitable for food-grade items like chocolate, candy, fondant, resin, plaster, and soap.

|

|

||

|

4

|

This product is ideal for making molds at home using silicone rubber with a mixing ratio of 1:1.

|

|

||

|

5

|

The product is ideal for making molds for casting resin, silicone, and candle-making.

|

|

||

|

6

|

The product is ideal for creating molds to cast resin, wax, soap, plaster, and clay in DIY projects.

|

|

||

|

7

|

Ideal for making molds for food, plaster, candles, and 3D objects with fast curing, tear-resistant, and durable silicone rubber.

|

|

||

|

8

|

It is ideal for creating molds for food-safe materials such as chocolate, soy wax, low melt soaps, and resins.

|

|

||

|

9

|

It is ideal for making molds for various materials such as epoxy resin, wax, soap, plaster, cement, and more.

|

|

||

|

10

|

Ideal for creating food-safe silicone molds to cast epoxy and polyurethane resin products.

|

|

1. Clear Diy Silicone Mold Making Kit

The Premium Molds Making Silicone Material offered by LET'S RESIN is the perfect choice for hobbyists and beginners alike. Made from platinum-cured silicone, this translucent liquid silicone is non-toxic, safe, and odor-free, making it a great option for those with sensitive skin. It is also soft, flexible, and clear, giving you the best results every time.

Mixing and pouring this silicone molds making kit is incredibly easy. It comes with part A and part B, with a mix ratio of 1:1 by weight. Simply pour the parts together and stir the silicone rubber for 5 minutes. Thoroughly stirring the liquid silicone rubber mixture ensures the best results. The working time for this mold making kit is 5 minutes at room temperature.

Bubbles can be a problem when making molds, but not with LET'S RESIN's Premium Molds Making Silicone Material. The bubbles will automatically disappear within 2 hours without the need for vacuum degassing. The curing time of the silicone rubber varies depending on the size and thickness of the mold, but it is at least 12 hours at room temperature. If the silicone rubber is a little sticky, extending the curing time will do the trick.

This mold making kit is great for beginners and those new to the craft. No special skills or tools are required, making it easy for anyone to enjoy this fun and creative activity all day. Cleaning up is also a breeze with soapy water or rubbing alcohol.

This Premium Molds Making Silicone Material has a wide range of applications, making it ideal for art craft use. You can DIY your own resin molds, wax molds, candle molds, soap molds, and use it to make silicone molds for resin casting, wax, candle, soap making, and more. However, it is not suitable for making food molds. If you have any questions about this molding silicone kit, LET'S RESIN is always happy to help.

2. Translucent Silicone Mold Kit For Resin Casting

The silicone mold making kit is a user-friendly product that requires no special skills or tools to operate. The kit comprises of two parts, A and B, with a mixing ratio of 1:1 by weight. To use, simply pour both parts into a mixing container and stir for 5-6 minutes, ensuring that the mixture is thoroughly blended for optimal results.

The silicone rubber used in the kit is of high quality and safe, made from non-toxic and odorless materials. It is also very flexible, soft, and transparent, making it a reliable and easy-to-use option for mold making.

The product is also premium, with self-debubbling properties that ensure all bubbles disappear within two hours without the need for vacuum degassing. The curing time for the rubber is approximately 12 hours at room temperature, but this can vary depending on the mold size and thickness. It is important to note that curing time is affected by temperature, and cooling can slow down the process if it is too fast, while heating can accelerate it if it is too slow.

The silicone mold making kit is suitable for a wide range of applications, including making resin molds, wax molds, candle molds, soap molds, and casting molds. However, it is important to note that it is not suitable for making food molds.

When using the kit, it is recommended to avoid mixing without a silicone cup or molding without a silicone mold as they will fuse. Additionally, certain chemicals, like sulphur, can inhibit the curing process, so it is important not to use sulphur plasticine clay.

3. Diy Silicone Mold Kit – Food Grade & Easy!

Creating molds has never been easier with this product. By simply mixing equal parts of A (White) and B (Blue) by hand until a uniform color is achieved, molds can be created without the need for mixing containers, mold boxes, or degassing equipment. This mold-making material is designed to stay put on almost any surface, even vertical ones, and produces strong, flexible, reusable, commercial-quality molds.

Whether one is a beginner or a professional, this product is perfect for anyone who wants to make molds right the first time. With a generous 15-20 minute work time, maximum detail capture on small and large objects is possible. Moreover, demold time only takes 60-75 minutes at room temperature. For those in a hurry, applying heat with a hair dryer can greatly reduce demold time.

This mold-making material has been tested and certified to be food-grade compliant and non-toxic. A certified lab has conducted extraction tests to confirm that it is safe for both water-based and fat-based foods. It is odor-free, BPA-free, and is made entirely in the USA.

This product is recommended for a variety of food applications, including chocolate, fondant, gummies, edibles, butter, fudge, cookie dough, marzipan, ice, candy, gelatin, cake decorating, beer brewing, wine making, and more. It is also perfect for non-food uses, such as clays, resins, epoxies, prototype reproduction, PMC and polymer clay, soap, art restoration, sculpture, plaster, wax, low melt metals, jewelry making, tabletop gaming, cosplay, 3D printing, DIY gaskets and seals, concrete, and more.

4. Resin Mold Kit: Blue Silicone Mix

This premium blue silicone rubber is a top-quality material that is safe and non-toxic, making it ideal for making molds. It boasts a hardness of 30A, which ensures that your molds will be durable and flexible. This silicone molds making kit consists of two parts, part A and part B, which should be mixed in a 1:1 ratio by weight. Simply pour the two parts together and stir the mixture thoroughly for 3-5 minutes to ensure that it is well-mixed.

One of the great features of this product is that it produces molds without any bubbles, which means that there is no need for vacuum degassing. Any bubbles that may appear will automatically disappear within 2 hours. The working time of the blue making mold kit is 5 minutes at room temperature, and the curing time is about 8-12 hours at room temperature. However, the curing time may vary depending on the size and thickness of your mold. If the silicone molding rubber is a little sticky, you can extend the curing time for better results.

This mold making kit is perfect for beginners who are new to silicone mold making. You don't need any special skills or tools to use this product, so you can enjoy this fun and creative activity all day long. If you accidentally spill any of the mixture, simply clean it up with soapy water or rubbing alcohol.

This blue molds making silicone kit is ideal for a wide range of applications, including art and craft use, DIY resin molds, wax molds, candle molds, and more. It is perfect for making molds for resin, wax, soap, casting, and other similar materials. However, it is important to note that this product should not be used for making food molds.

5. Silicone Mold Kit For Resin, Candle & More.

The LET'S RESIN Mold Making Kit boasts premium quality molds that are safe and odorless. Made from platinum-cured silicone, this translucent clear liquid silicone is perfect for making molds that are highly flexible, tear-resistant, and can last for a long time. It's ideal for detailed molds and even 3D silicone molds.

Mixing and pouring this silicone mold making kit is easy with its 2-part silicone feature that consists of part A and part B. Simply pour both parts together and stir for 5 minutes to ensure a thorough mixture.

Another great feature of this mold making kit is its self-degassing and no bubbles feature. The low viscosity of the liquid silicone causes bubbles to disappear within 2 hours without the need for vacuum degassing. Working time is within 30 minutes, and cure time is 3-6 hours at room temperature. The curing time may vary depending on the mold size and thickness, but it can be extended if necessary. To reduce micro bubbles, the silicone can be sealed and stored in the refrigerator for 1 hour before continuing to cure at room temperature.

LET'S RESIN Mold Making Kit is perfect for beginners who are new to silicone mold making. No special skills or tools are required, making it a fun and creative activity for all ages. Cleaning up any spillage is easy and can be done with soapy water or rubbing alcohol.

This kit is versatile and can be used for various applications such as art and craft use, DIY resin molds, wax molds, candle molds, and more. The possibilities are endless with LET'S RESIN rubber mold making kit.

For any inquiries or concerns, the LET'S RESIN team is always ready to assist you. Try this kit now and experience the convenience and quality of premium silicone mold making.

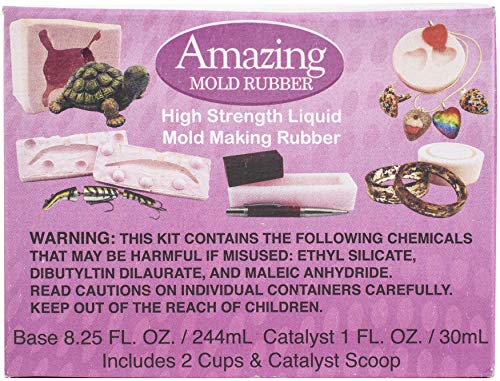

6. Diy Mold-Making Magic With Alumilite

The Amazing Mold Rubber is the perfect solution for creating an exact replica of any object. This professional-grade silicone mold produces highly detailed molds that can capture even the tiniest details of the original. Whether you're creating one-piece molds with undercuts or complex multiple-piece molds, this mold rubber will deliver the results you're looking for.

The strength of this mold rubber is unparalleled. Once you're ready to cast, you won't need to worry about damaging the mold. It is highly flexible and has a very high tear strength, ensuring that it will remain exactly as it is.

One of the best things about the Amazing Mold Rubber is its fast demolding time. It can be demolded in as little as 2-4 hours. However, the more humid and warmer the environment, the quicker it will cure. So, it's important to plan when and where you'll do your next project.

Mixing the Amazing Mold Rubber is incredibly easy. Just follow the mix ratio by weight of 10:1 base to catalyst formula to get the right proportion you need for your molding project. To make mixing even more convenient, cups and scoops are provided in the kit.

This silicone rubber molder has a wide range of uses. It is ideal for making resin, wax, candle, soap, and casting molds. With this mold rubber, you can make molds of any size and shape according to what you need and desire.

7. Platinum Cast Kit: Mold, Pour, Create & Repeat

The Unicone Art Silicone Mold Making Kit is a top-notch choice for those seeking a reliable and safe mold making material. This platinum-based kit is non-toxic, odorless, and environmentally friendly, making it a great option for home use.

This versatile kit is compatible with a variety of materials, including casting resins, wax, gypsum, Jesmonite, concrete, soap, and candles. It can also be used to create molds for candy, chocolate, cake, and ice cubes.

The Unicone Art Silicone Mold Making Kit is designed to reproduce perfect detail, making it an excellent choice for home projects. Its high-temperature resistance and tear-resistant formula ensure that it is versatile and durable. It is also food safe, making it a great option for creating molds for edible items.

The NO BUBBLE formula of this kit ensures that no pressure pot is needed for degassing. The easy mix extremely thin viscosity, 1:1 ratio, and signature blue pigment make it easy to see the two parts mix together.

This kit cures quickly, with a 3-5 hour cure time and 40 minutes of work time. Its soft, flexible, and strong material makes it easy to release molds, while its perfect size kit makes 4 lbs. worth of projects. Additionally, these molds can be used over and over again, making them a cost-effective option.

Unicone Art produces high-quality art supplies that are made for artists, by artists. The Silicone Mold Making Kit is a testament to their commitment to quality and innovation. With this kit, artists can create unique molds for their masterpieces.

8. Fleximold: Reusable, Safe, Custom Molding Magic

Introducing the Food Safe Mold Making Gel, a versatile and convenient solution for creating food-safe molds. This mold making gel is ideal for making molds of chocolate tools, chocolate game pieces, and other soft casting materials such as wax and soap.

The Food Safe Mold Making Gel boasts a flexible and low bubble formation, making it easy to work with and ensuring a smooth finish on your final product. This mold making gel is also BPA free, eco-friendly, and food contact safe, making it a reliable and safe choice for mold making in the kitchen.

The Food Safe Mold Making Gel conforms to ASTM D-4236, ensuring that it meets the highest quality standards and is non-toxic. It can be melted in the microwave, a double boiler, or an oven set no higher than 200 F, providing you with a range of options for melting and molding your desired material.

One of the best things about the Food Safe Mold Making Gel is that it is reusable for dozens and dozens of unique molds. This means that you can create a wide variety of molds for different purposes, and reuse them whenever you want something new.

Best Mold Material For Casting Resin FAQs

Are there any natural materials that can be used to make molds for casting resin?

Yes, there are several natural materials that can be used to make molds for casting resin. One of the most popular materials is silicone, which is a flexible and durable material that can be easily molded to create a variety of shapes and designs. Another natural material that can be used is latex, which is also flexible and can be used to create detailed molds.

Other natural materials that can be used for mold making include clay, plaster, and alginate. Clay is a great option for creating larger molds, while plaster is ideal for creating smaller, more intricate molds. Alginate, which is derived from seaweed, is a popular choice for making highly detailed molds of body parts, such as hands or feet.

When using natural materials for mold making, it is important to ensure that they are properly prepared and sealed to prevent the resin from sticking or leaking. Additionally, it is important to follow all safety guidelines when working with resin, as it can be toxic if not handled properly.

Can 3D printed molds be used for casting resin, and if so, what types of materials are best?

Yes, 3D printed molds can be used for casting resin. However, it is important to choose the right type of material for the mold to ensure successful casting.

The best materials for 3D printed molds for casting resin are typically those that are strong, heat-resistant, and have a smooth surface finish. Some of the most commonly used materials include ABS, PLA, PETG, and Nylon. These materials can withstand the heat and pressure of the casting process, and their smooth surface finish ensures that the resin will not stick to the mold.

It is also important to consider the design of the mold when choosing the material. For example, molds with intricate details may require a more flexible material to ensure easy removal of the final product.

Overall, 3D printed molds can be a cost-effective and efficient way to create custom molds for casting resin. By choosing the right material and design, you can ensure successful and high-quality castings.

Can latex molds be used for casting resin, and if so, what are the advantages and disadvantages?

Yes, latex molds can be used for casting resin. One of the advantages of using latex molds for casting resin is that they are flexible and can easily release the casted object. Latex molds are also durable and can withstand multiple uses. They can also capture fine details and textures of the original object, resulting in a high-quality cast.

However, there are some disadvantages to using latex molds for casting resin. One of the main issues is that latex molds can be expensive and time-consuming to make. Additionally, they require a mold release agent to prevent the resin from sticking to the mold. Latex molds can also be prone to tearing or stretching if not properly maintained, which can affect the quality of the cast.

Overall, the use of latex molds for casting resin can be a good option depending on the project requirements and budget. It is important to understand the advantages and disadvantages in order to make an informed decision.

How do you determine the appropriate mold release agent to use with a specific mold material when casting resin?

Selecting the appropriate mold release agent is crucial when casting resin to ensure that the final product is of high quality and has a smooth surface finish. The compatibility of the mold release agent with the mold material is essential to prevent damage to the mold and ensure that the resin does not stick to the mold surface.

When selecting a mold release agent, it is important to consider the type of mold, the curing process of the resin, and the desired surface finish. Silicone molds typically require a silicone-based release agent, while polyurethane molds require a non-silicone release agent. For molds with intricate details, a higher viscosity release agent is recommended to ensure that all areas are covered.

The curing process of the resin also affects the selection of the mold release agent. For resins that cure quickly, a fast-drying release agent is ideal to prevent any delays in production. On the other hand, slow-curing resins require a release agent that can withstand prolonged exposure to the resin without breaking down.

Lastly, the desired surface finish of the resin also plays a role in selecting the appropriate mold release agent. For a high gloss finish, a wax-based release agent is recommended, while a semi-gloss or matte finish requires a release agent that does not contain wax.

Overall, selecting the appropriate mold release agent requires consideration of the type of mold, curing process of the resin, and desired surface finish to ensure a successful casting process.

How do you properly prepare a mold for casting resin to ensure a successful outcome?

Preparing the mold is a crucial step in the resin casting process to ensure a successful outcome. Here are some steps to properly prepare a mold for casting resin:

1. Clean the mold: Before starting the casting process, the mold must be thoroughly cleaned to remove any dirt, dust, or debris that might interfere with the final outcome. You can clean the mold with soap and water or rubbing alcohol.

2. Apply a release agent: A release agent is a substance that helps to prevent the resin from sticking to the mold. There are many types of release agents available, such as silicone spray, petroleum jelly, or mold release wax. Apply a thin layer of the release agent to the mold and let it dry.

3. Seal the mold: If the mold has any cracks or holes, it is important to seal them with a suitable material, such as silicone caulk or epoxy putty. This will prevent the resin from leaking out and ruining the final product.

4. Prepare the resin: Follow the manufacturer's instructions to prepare the resin. Make sure to measure the resin and hardener accurately and mix them thoroughly.

5. Pour the resin: Slowly pour the resin into the mold, being careful not to overfill it. If there are any air bubbles, you can use a heat gun or a torch to remove them.

6. Cure the resin: Allow the resin to cure according to the manufacturer's instructions. Once it is fully cured, you can remove the casting from the mold.

By following these steps, you can prepare a mold for casting resin and achieve a successful outcome.

What are the benefits of using a vacuum chamber when casting resin in a mold?

When casting resin in a mold, using a vacuum chamber can provide several benefits. Firstly, it helps to remove air bubbles from the resin, which can be difficult to eliminate by other means. The vacuum chamber creates a low-pressure environment that allows air bubbles to rise to the surface of the resin and escape. This results in a smoother and more even finish on the final product.

Secondly, using a vacuum chamber can help to reduce the curing time of the resin. By removing the air bubbles, the resin can cure more evenly and quickly, resulting in a stronger and more durable final product.

Finally, using a vacuum chamber can help to reduce waste by ensuring that the resin fills the mold completely. This is particularly important when casting intricate or detailed molds, as it can be difficult to get the resin into all of the small spaces without air pockets.

Overall, using a vacuum chamber when casting resin in a mold can result in a higher quality and more efficient casting process.

What are the most commonly used mold materials for casting resin?

When it comes to casting resin, there are a variety of mold materials that can be used depending on the specific project needs. However, the most commonly used mold materials for casting resin are silicone, urethane rubber, and latex.

Silicone is a popular choice because it is flexible, durable, and heat-resistant. It can be used to create highly detailed molds that can be reused multiple times. Urethane rubber is also a popular choice because it is easy to work with and can be poured directly onto the object being molded. It has good tear strength and can be used to create molds with intricate details.

Latex is another commonly used mold material, especially for smaller projects. It is easy to use and can be applied directly to the object being molded. However, it is not as durable as silicone or urethane rubber and may need to be replaced more frequently.

Ultimately, the choice of mold material will depend on the specific project needs, including the size and complexity of the object being molded, the desired level of detail, and the number of molds needed.

What are the pros and cons of using metal molds for casting resin?

Using metal molds for casting resin has its own set of advantages and disadvantages. One of the biggest advantages of using metal molds is their durability. Metal molds can withstand high temperatures and pressures, making them ideal for casting resin. They also offer a high level of detail, allowing for intricate designs to be created with ease. Metal molds are also reusable, making them an affordable option for mass production.

On the other hand, metal molds can be expensive to produce initially and may require a significant amount of time for design and fabrication. They can also be heavy and difficult to handle, which could be a challenge for some users. Additionally, metal molds may require a release agent to prevent the resin from sticking to the mold, which can add to the cost and complexity of the casting process.

Overall, the decision to use metal molds for casting resin will depend on the specific needs of the project. While they offer many benefits, it's important to consider the cost, complexity, and potential challenges of using metal molds before deciding to incorporate them into your process.

What factors should be considered when choosing a mold material for casting resin?

When choosing a mold material for casting resin, there are several factors that should be considered. First, the mold material should be compatible with the type of resin being used. Some resins may require a specific type of mold material to ensure proper curing and release from the mold.

Second, the mold material should be able to withstand the temperature and pressure of the resin casting process. For example, silicone molds are a popular choice for resin casting because they can withstand high temperatures and pressure without degrading or warping.

Third, the mold material should be able to provide a smooth and detailed surface finish on the final casting. Some mold materials may leave a rough or textured surface on the casting, which may not be desirable depending on the intended use of the finished product.

Finally, the cost and availability of the mold material should also be considered. Some mold materials may be more expensive or difficult to source than others, and this may impact the overall cost and feasibility of the resin casting project.

What types of silicone molds are best for casting resin?

When it comes to casting resin, silicone molds are the most preferred choice due to their flexibility and durability. There are various types of silicone molds available in the market, but not all of them are suitable for casting resin. The best types of silicone molds for casting resin are:

1. Smooth-Sided Silicone Molds: These types of molds are perfect for casting resin as they produce a smooth and shiny finish. They are also easy to release the resin from, and they don't require any release agents.

2. Flexible Silicone Molds: Flexible silicone molds are ideal for casting resin as they can be easily bent and twisted to release the resin. They are also durable and can withstand high temperatures.

3. Clear Silicone Molds: Clear silicone molds are perfect for casting resin as they allow you to see the object inside the mold. They also produce a glossy finish.

4. Textured Silicone Molds: Textured silicone molds are great for creating unique and intricate designs on your resin castings. They come in a variety of textures and patterns, making it easy to create different effects.

In conclusion, when selecting a silicone mold for casting resin, it's important to consider the type of mold that will best suit your project needs.