If you’re looking for the perfect sawzall blade to cut through metal, you’re in the right place. A sawzall is a versatile tool used for cutting through different materials such as metal, wood, and plastic. However, when it comes to cutting through metal, choosing the right blade can make all the difference.

Before buying sawzall blades for metal, there are several factors to consider. It's essential to consider the blade's material, thickness, length, and teeth per inch (TPI) as they all impact performance. The TPI is an essential factor to consider since this determines the speed and the quality of the cut. Additionally, getting a blade that is constructed with durable materials will help you save money in the long run, as it means the blade will last longer.

Are you new to sawzall blades, or are you looking for an upgrade? Here are some questions to consider before making a purchase: Do you want a blade with straight or curved teeth? What TPI is needed for your work? What is the thickest metal you will be cutting? Knowing the answers to these questions will help you make an informed decision when it comes to choosing the best sawzall blade for metal.

In summary, choosing the perfect sawzall blade for metal involves evaluating blade material, thickness, length, and TPI. Don't forget to consider what types of metal you'll be cutting and at what thickness. With these factors in mind, you’re sure to find a sawzall blade that can effortlessly handle even the toughest metal cutting tasks.

10 Best Sawzall Blades For Metal

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

Ideal for fast and efficient cutting through wood or other tough materials with its 9-14 teeth per inch.

|

|

||

|

2

|

The product is ideal for cutting through a variety of materials with precision and speed.

|

|

||

|

3

|

Ideal for cutting through metal with reciprocating saws.

|

|

||

|

4

|

This product is ideal for cutting through metal with its 6 inch length and 8 teeth carbide tip blade.

|

|

||

|

5

|

This product is ideal for cutting through various materials with a reciprocating saw.

|

|

||

|

6

|

The product is ideal for cutting through a variety of materials with a reciprocating saw.

|

|

||

|

7

|

This product is ideal for cutting through metal materials with a reciprocating saw.

|

|

||

|

8

|

The product is ideal for cutting through various materials with a reciprocating saw.

|

|

||

|

9

|

It is ideal for cutting through a variety of materials with its bi-metal construction and 18 teeth per inch.

|

|

||

|

10

|

Ideal for fast and efficient cutting of metal materials with medium thickness.

|

|

1. Db Demo Demon 9 8-14tpi 25pk

Introducing the Variable Tooth, a powerful cutting tool designed to make your cutting tasks easier and more efficient. Measuring at 22.098 L x 3.302H x4.572W (centimeters), this tool is compact and easy to handle, yet powerful enough to tackle even the toughest cutting jobs.

One of the standout features of the Variable Tooth is its innovative variable tooth technology. This technology allows for faster cuts with less vibration, making your cutting experience smoother and more precise. Whether you are working on a DIY project at home or a professional job site, the Variable Tooth will help you get the job done quickly and efficiently.

At just 2.25 pounds, the Variable Tooth is lightweight and easy to maneuver, yet sturdy enough to withstand heavy use. Its durable construction ensures that it will be a reliable tool for years to come, making it a worthwhile investment for both DIY enthusiasts and professionals alike.

2. Diablo Ds0912bw25 Demo Demon 9 In. Reciprocating Saw Blade (25-Pack)

Looking for a reliable saw blade that can effortlessly cut through various materials? Look no further than this high-quality saw blade from Switzerland.

This saw blade is designed to provide efficient and accurate cuts, thanks to its superior build quality and durable materials. The blade is crafted from premium-grade steel, ensuring it can handle even the toughest cutting tasks with ease.

With a package weight of 1.407 kilograms, this saw blade is both sturdy and easy to handle. It measures 2.9 cm in length, 4.7 cm in width, and 29.0 cm in height, making it a convenient size for a wide range of cutting applications.

Whether you're a professional carpenter or a DIY enthusiast, this saw blade is sure to impress. It delivers precise and consistent cuts, and its high-quality construction ensures it will last for years to come.

So why wait? If you're in need of a high-quality saw blade that won't let you down, be sure to check out this product from Switzerland today!

3. Freud-Diablo 6 In Carb Tip Metal Recip 3 Pk

Introducing the 6 IN CARB TIP METAL RECIP 3 PK, a set of three high-quality reciprocating saw blades designed to make your cutting tasks easier and more efficient. These blades are made of durable and premium-quality carbide, making them ideal for cutting through metal, wood, and other tough materials.

Each blade measures 6 inches in length, providing ample blade surface area for your cutting needs. The carbide tip ensures that the blade stays sharp even after multiple uses, and the metal construction gives it the strength to handle tough cutting jobs. These blades are compatible with most standard reciprocating saws, making them a versatile addition to your tool collection.

Whether you're a professional contractor or a DIY enthusiast, the 6 IN CARB TIP METAL RECIP 3 PK is an excellent choice for your cutting needs. These blades are designed to be long-lasting and efficient, allowing you to get more done in less time. They are perfect for cutting through metal pipes, nails, and other materials that are difficult to cut with traditional saw blades.

In addition to their high-quality construction, these blades are also easy to use. They feature a standard shank that fits into most reciprocating saws, and they are simple to install and remove. With their efficient cutting power and easy operation, the 6 IN CARB TIP METAL RECIP 3 PK is a must-have tool for anyone who needs to cut through tough materials.

4. Freud Ds0608cf3 Diablo Reciprocating Blade 6" X 8t Carbide Tip Metal Cut 3 Per Package

Introducing the 6 IN CARB TIP METAL RECIP 3 PK, a must-have tool for any DIY enthusiast or professional contractor. This set includes three durable and high-quality metal reciprocating saw blades, each measuring six inches in length.

Crafted with precision and expertise, these blades feature carbide tips that make them ideal for cutting through tough materials such as metal, wood, and plastic. The carbide tip also ensures that the blades have a longer lifespan and maintain their sharpness over time, making them a reliable choice for any cutting job.

These blades are designed to fit most reciprocating saws, making them a versatile addition to any toolkit. They are compatible with a range of saw brands, including DeWalt, Bosch, and Milwaukee, among others.

The 6 IN CARB TIP METAL RECIP 3 PK blades are also engineered to provide smooth and efficient cutting performance. This means that users can achieve precise and accurate cuts, even in tight spaces and hard-to-reach areas.

Whether you're working on a DIY project at home or tackling a large-scale construction job, the 6 IN CARB TIP METAL RECIP 3 PK blades are an essential tool that will help you get the job done right. So why wait? Invest in this reliable and durable set today and take your cutting game to the next level!

5. Power Blast 8" Reciprocating Blades – 25-Pack

This durable and long-lasting blade is made with bi-metal construction, making it a reliable tool for any metal cutting task. The blade is strengthened with Power Blast Technology, which reduces breaks and ensures smooth cutting. Its versatile design allows it to easily cut through thin and medium metals, making it a go-to choice for any metalwork project.

The T2 Technology incorporated in the blade allows for efficient cutting in a wide range of materials, making it a versatile tool for any job. Its tooth design delivers up to twice the life of other blades, while also making heavy materials easier to cut. The bi-metal construction of the blade allows it to bend and flex without breaking, making it a safe and reliable tool to use.

Designed to minimize friction and heat build-up, this blade is perfect for cutting through a wide variety of metal materials. Its 18 tooth per inch design makes it ideal for use with medium-thickness metals, ensuring a smooth and accurate cut every time. Whether you're an experienced metalworker or just starting out, this blade is a must-have for any metal cutting project.

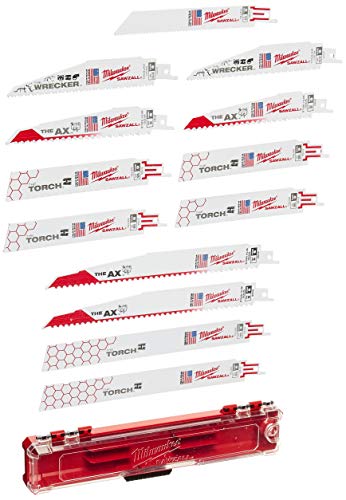

6. Milwaukee Electric Tool 49-22-1129 Sawzall Reciprocating Saw Blade Set, 12 Pc, White

The Thick Blades with .042-inch and .062-inch thickness are the perfect solution for high-intensity applications. These blades are designed to withstand heavy-duty usage and provide unmatched durability and strength. With a height of 1-inch, these blades offer added strength, making them ideal for tough cutting jobs.

One of the standout features of these blades is their width, which allows them to fit into tight spaces with ease. This feature makes them highly versatile and practical, as they can be used in a variety of applications, even in the most challenging environments.

Whether you are working in construction, landscaping, or other heavy-duty industries, these blades are the perfect choice to get the job done efficiently and effectively. With their robust design, they can withstand significant wear and tear, ensuring that they last longer than other blades on the market.

7. Ezarc Cobalt Sabre Blades For Metal (5-Pack)

Introducing the EZARC Reciprocating Saw Blades, designed with long-lasting teeth that are made of bi-metal with 8% cobalt. This unique composition sets them apart from normal bi-metal blades and provides a 2-times longer lifespan.

These blades are a metal master, equipped with a hard cobalt edge that allows effortless cutting into sheet metal, metal pipe, and profile. With a cutting capacity that can handle medium to thick sheet metals between 3-8mm and solid pipes/profiles with a diameter of less than 100mm, the EZARC Reciprocating Saw Blades are versatile and effective.

The optimized design of these blades features a 0.9 thin wall and set teeth design that helps to reduce heat buildup and maximize cutting efficiency. With this design, users can experience a smoother, more efficient cutting process without worrying about blade overheating.

In addition, the universal shank of these blades measures 1/2 inch, making it compatible with all Sawzall tools on the market. This includes popular brands such as Bosch, Dewalt, Milwaukee Sawzall Saw, SKIL, Makita, Black & Decker, Ryobi, Porter Cable, Hitachi, Flex, Hilti, Metabo, and more.

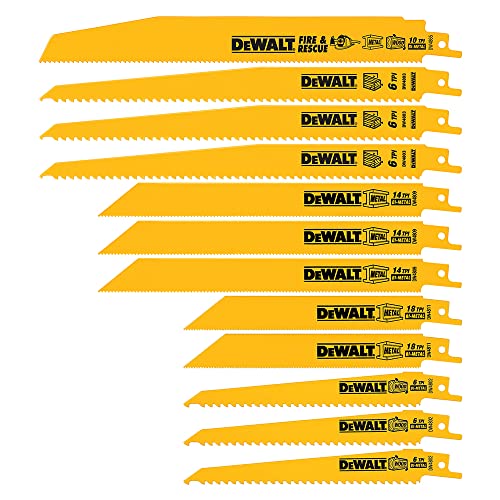

8. Dewalt Reciprocating Saw Blades, Bi-Metal Set With Case, 12-Piece (Dw4892)

Looking for a reliable selection of reciprocating saw blades for your common applications? Look no further than the Combination Sets from DEWALT.

This set includes a variety of blade sizes that are perfect for a range of cutting needs. Whether you're working on a DIY project or a professional job, these blades will get the job done quickly and efficiently.

One of the standout features of this set is the Telescoping ToughCase container. This innovative container expands to hold multiple blade sizes, making it easy to keep all your blades organized and in one place. Plus, it can fit in your DEWALT power tool kit box, so you can easily take it with you on the go.

Another great feature of these blades is that they are Made In The USA With Global Materials. This means that you can trust that they are made with high-quality materials and that they are built to last.

But what really sets these blades apart is their extreme durability. Thanks to the Iron Blast Technolog surface enhancement, these blades are strengthened to resist fatigue and teeth stripping. This means that you can use them for even the toughest jobs without worrying about them wearing down.

9. Dewalt Reciprocating Saw Blades, Bi-Metal, 6-Inch, 18 Tpi, 100-Pack (Dw4811b)

Introducing the DEWALT reciprocating saw blade range, designed to provide efficient cutting and long-lasting performance for your cutting needs. With patented toothforms, these blades optimize chip removal for up to 50% longer life compared to prior generation DEWALT blades. These blades are built to last with a bi-metal construction that delivers flexibility and a durable cutting edge.

The DEWALT blade range is made in the USA with global materials, ensuring top-notch quality and performance. These blades are compatible with a variety of reciprocating saws and are suitable for a range of cutting applications.

Investing in DEWALT blades means investing in a reliable and efficient cutting solution that will save you time and money in the long run. With their superior design and construction, these blades are a must-have for any contractor, DIY enthusiast, or homeowner looking for a blade that can keep up with their cutting needs.

Best Sawzall Blades For Metal FAQs

Are there any safety precautions I should take when using sawzall blades for metal?

Yes, there are certain safety precautions that you should take when using sawzall blades for metal. Firstly, you should always wear protective gear such as safety glasses, earplugs, and gloves to prevent injury from metal shards or debris. It's also important to ensure that the blade is securely attached to the saw and that the saw is being held firmly while in use.

Additionally, you should always use the appropriate blade for the type of metal you are cutting. Using the wrong blade or a dull blade can cause the saw to kickback, which can result in serious injury. It’s also important to avoid cutting through any electrical wires or pipes that may be hidden within the metal you are cutting.

Lastly, you should always follow the manufacturer's instructions and guidelines for operating the saw. This includes using the correct speed setting, avoiding cutting near the edge of the material, and not forcing the blade through the metal. By following these safety precautions, you can ensure that you are using sawzall blades for metal safely and effectively.

Can sawzall blades for metal be used on other materials?

Sawzall blades for metal are specifically designed to cut through hard and dense materials such as steel, iron, and other metals. However, these blades can be used on other materials as well depending on the thickness and density of the material. For instance, sawzall blades for metal can also be used to cut through wood, fiberglass, and plastic, but the cutting speed may vary depending on the material.

It is worth noting that using sawzall blades for metal on materials other than metal may reduce their lifespan and effectiveness. Additionally, it is important to choose the right blade for the specific material you intend to cut as using the wrong blade can result in poor cuts, damage to the material, and even safety hazards. Therefore, it is advisable to consult the manufacturer's recommendations before using sawzall blades for metal on materials other than metal.

How do I choose the right thickness of sawzall blade for cutting metal?

Choosing the right thickness of sawzall blade for cutting metal is important to ensure a clean and efficient cut. The thickness of the blade will determine the speed and accuracy of the cut, as well as the durability of the blade. The thickness of the blade will depend on the type and thickness of the metal being cut.

For thinner metals such as sheet metal or thin pipes, a thinner blade with a thickness of 14 to 18 teeth per inch (TPI) would be suitable. A thicker blade with 10 to 14 TPI would be more appropriate for cutting thicker metal such as steel pipes or rods.

It is important to note that the blade material should also be considered when choosing the right blade thickness. High-speed steel blades are suitable for cutting softer metals, while bi-metal blades are more durable and can handle tougher metals.

Ultimately, it is important to choose a blade that matches the specific cutting needs and the type of metal being cut. It is also important to follow the manufacturer's recommendations for blade selection based on the saw’s capacity and power.

How do I know if I need a fine-tooth or coarse-tooth sawzall blade for cutting metal?

When it comes to cutting metal with a sawzall, selecting the right blade is crucial for achieving the desired outcome. The choice between a fine-tooth or coarse-tooth sawzall blade depends on the thickness and type of metal you are cutting.

For thinner metals, such as sheet metal or thin tubing, a fine-tooth blade is recommended. The smaller teeth on a fine-tooth blade make smoother and cleaner cuts, preventing the metal from warping or bending. On the other hand, for thicker metals like steel beams or pipes, a coarse-tooth blade is the better option. Coarse-tooth blades have larger teeth that allow for faster and more aggressive cuts on thicker materials.

It's important to note that the type of blade material also plays a role in the cutting process. Bi-metal blades are designed for cutting through a wide range of materials, including metals, while carbide-tipped blades are ideal for cutting through hardened metals.

In summary, determining whether to use a fine-tooth or coarse-tooth sawzall blade for cutting metal depends on the thickness and type of metal you are cutting. For thin metals, use a fine-tooth blade, while for thicker metals, use a coarse-tooth blade.

How do I properly maintain my sawzall blades for cutting metal?

Proper maintenance of your sawzall blades is crucial to ensure that they cut through metal efficiently and effectively. Here are some tips on how to maintain your sawzall blades for cutting metal:

1. Clean the blades after each use: Use a clean cloth to wipe away any debris or metal shavings on the blade. This will prevent rust and corrosion.

2. Lubricate the blades: Apply a few drops of lubricant to the blade after cleaning. This will help to prevent the blade from overheating and prolong its lifespan.

3. Sharpen the blades: Over time, the blade can become dull and ineffective. You can use a file or sharpening stone to sharpen the blade. Be sure to follow the manufacturer's instructions for sharpening.

4. Store the blades properly: When not in use, store the blades in a dry place. You can also use a blade guard to protect the blade from damage.

By following these tips, you can ensure that your sawzall blades for cutting metal remain in good condition and perform at their best.

How long do sawzall blades for metal typically last?

The lifespan of sawzall blades for metal can vary depending on several factors such as the type of blade, the thickness and hardness of the metal being cut, and the intensity and frequency of use. Typically, high-quality sawzall blades for metal can last for several hundred cuts before they start to dull and lose their effectiveness. However, it's important to note that using a blade beyond its recommended lifespan can result in reduced efficiency and accuracy, as well as increased risk of accidents and injuries.

To maximize the lifespan of your sawzall blade for metal, it's important to choose the right blade for the job and ensure that it's properly installed and maintained. You should also avoid forcing the blade through the metal, as this can cause unnecessary wear and tear. Additionally, if you notice any signs of wear or damage on the blade, such as chipping or bending, it's important to replace it immediately to ensure safe and effective cutting.

What are the best brands of sawzall blades for cutting metal?

When it comes to cutting metal with a Sawzall, it's essential to use the right blade for the job. There are many brands of Sawzall blades available in the market, but not all of them are suitable for cutting metal.

Some of the best brands of Sawzall blades for cutting metal include Lenox, Diablo, and Milwaukee. Lenox blades are known for their durability and longevity, making them an excellent choice for heavy-duty metal cutting tasks. Diablo blades, on the other hand, are known for their precision and smoothness of cut, making them a great option for cutting thinner metals.

Milwaukee, a well-known brand in the power tool industry, also offers a range of Sawzall blades for metal cutting. Their blades are designed to withstand high-speed cutting and provide clean and precise cuts.

It's important to note that the best Sawzall blade for cutting metal will depend on the specific metal being cut, its thickness, and the type of Sawzall being used. It's always recommended to consult the manufacturer's guidelines and choose a blade that is specifically designed for the task at hand.

What are the best materials for sawzall blades for cutting metal?

When it comes to cutting metal with a sawzall, the blade you choose is critical to achieving a clean and precise cut. The best materials for sawzall blades for cutting metal are bimetal and carbide-tipped blades. Bimetal blades are made with two different metals, typically high-speed steel and a more durable metal like cobalt, making them strong and long-lasting. They are ideal for cutting through a wide range of materials, including metal, wood, and plastic. Carbide-tipped blades, on the other hand, are made with small pieces of tungsten carbide that are welded onto the blade's teeth. These blades are extremely durable and can cut through the toughest metals like cast iron, stainless steel, and high-tensile steel. It's important to note that when cutting metal with a sawzall, you should choose a blade with fewer teeth per inch (TPI) to prevent the blade from overheating and breaking. Overall, bimetal and carbide-tipped blades are the top choices for those looking to cut metal with a sawzall.

What is the difference between bi-metal and carbide-tipped sawzall blades for metal?

Bi-metal and carbide-tipped sawzall blades are both used for cutting metal, but they have some key differences. Bi-metal blades are made from two types of metal that are welded together, with a high-speed steel edge and a flexible spring steel body. This combination allows for the blade to be more durable and flexible, making it ideal for cutting through a range of metals, including nails and screws.

On the other hand, carbide-tipped blades are made from a harder material, with carbide teeth that are welded onto the blade. This makes them ideal for cutting through harder metals, such as cast iron and stainless steel. Carbide blades also tend to last longer than bi-metal blades, making them a better choice for heavy-duty applications.

Ultimately, the choice between bi-metal and carbide-tipped sawzall blades for metal depends on the specific needs of the job. For general-purpose cutting of softer metals, bi-metal blades are a good choice, while carbide blades are better suited for cutting harder metals that require a more durable blade.

What size sawzall blade is best for cutting metal?

When it comes to cutting metal with a sawzall, you need to select the right size of the blade for the task. Generally, a 6-inch or 8-inch blade is ideal for cutting through metal materials. These blades have a thickness of 0.035 inches, which is perfect for cutting through a variety of metal thicknesses. Additionally, the teeth per inch (TPI) of the blade is also an important factor to consider. For cutting through thinner metals, a blade with a higher TPI, such as 24 or 32, may be more suitable. However, for cutting through thicker materials, a blade with a lower TPI, such as 14 or 18, may be better. It is important to note that using the wrong size blade can result in damaged tools, inaccurate cuts, and safety hazards, so it is crucial to select the right size blade for the job.